You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

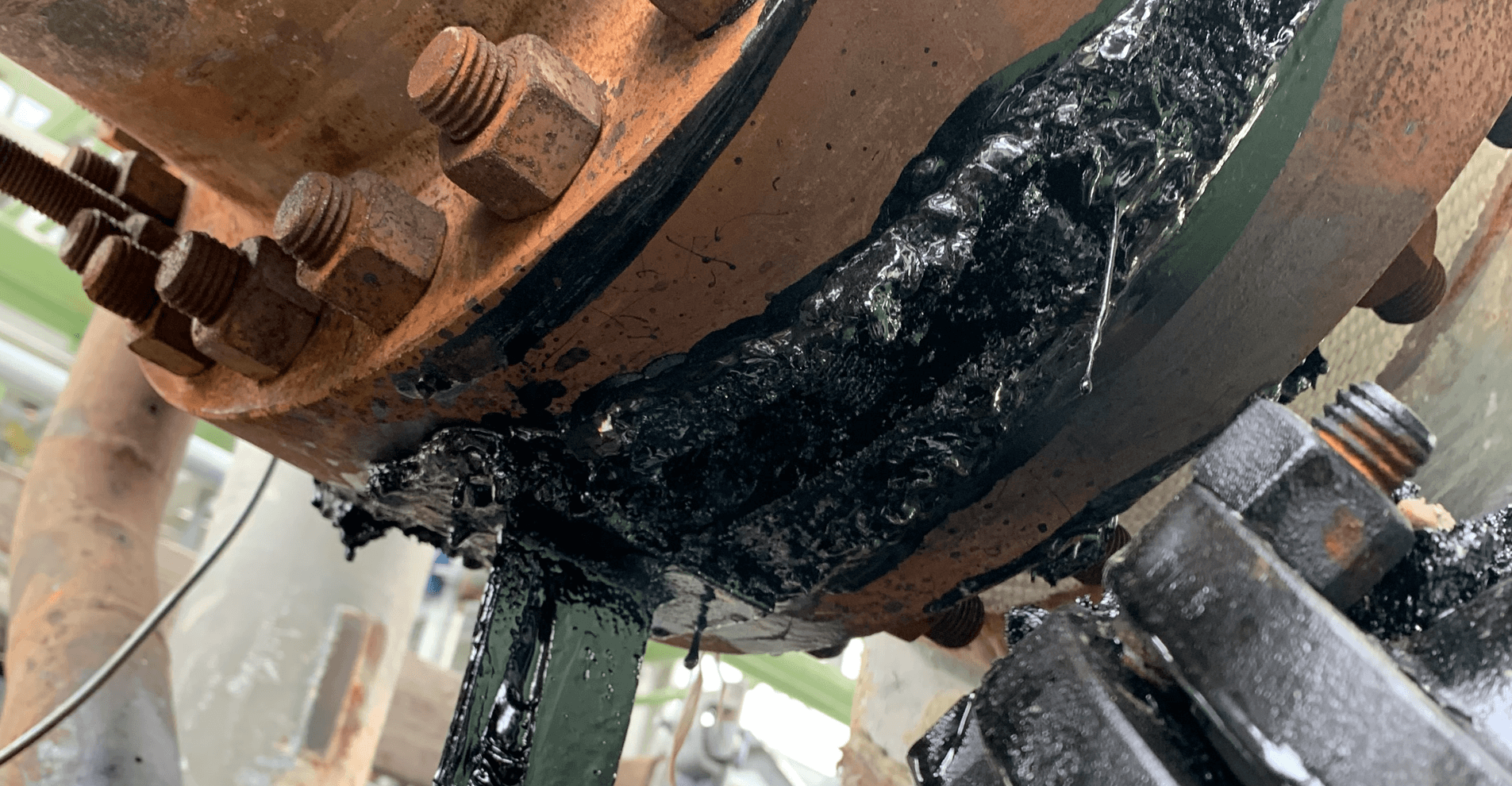

A prominent player in the Oil & Gas downstream sector faced a critical challenge in its operations. During the operation of a critical U-tube heat exchanger within a bio-propane unit, the customer encountered recurring hot oil leakages. In addition to environmental pollution from the leakages, a severe health and safety risk was present due to the potential ignition of the leaked hot oil. The heat exchanger operated under demanding thermal cycling conditions, with frequent, severe heating and cooling cycles every 7 - 8 hours which saw the hot oil reaching 370°C before cooling to ambient temperature.

A prominent player in the Oil & Gas downstream sector faced a critical challenge in its operations. During the operation of a critical U-tube heat exchanger within a bio-propane unit, the customer encountered recurring hot oil leakages. In addition to environmental pollution from the leakages, a severe health and safety risk was present due to the potential ignition of the leaked hot oil. The heat exchanger operated under demanding thermal cycling conditions, with frequent, severe heating and cooling cycles every 7 - 8 hours which saw the hot oil reaching 370°C before cooling to ambient temperature.

The U-tube heat exchanger was utilised for the regeneration process in a bio-propane unit. It processed hot oil and hydrogen under extreme thermal cycling conditions which involved remote control valves feeding media into the vessel. These conditions caused substantial loading and unloading conditions on the tube sheet flange connection due to the extreme cyclical service life, resulting in accelerated joint relaxation and reduced time to leakage.

The customer's initial approach involved the utilisation of an alternative standard kammprofile gasket with graphite facing. However, this solution failed to adequately address the challenges posed by relaxation over time due to the expansions and contractions taking place between flanges in intense thermal cycling conditions. The standard gasket's performance fell short, resulting in recurring leaks that posed significant safety concerns.

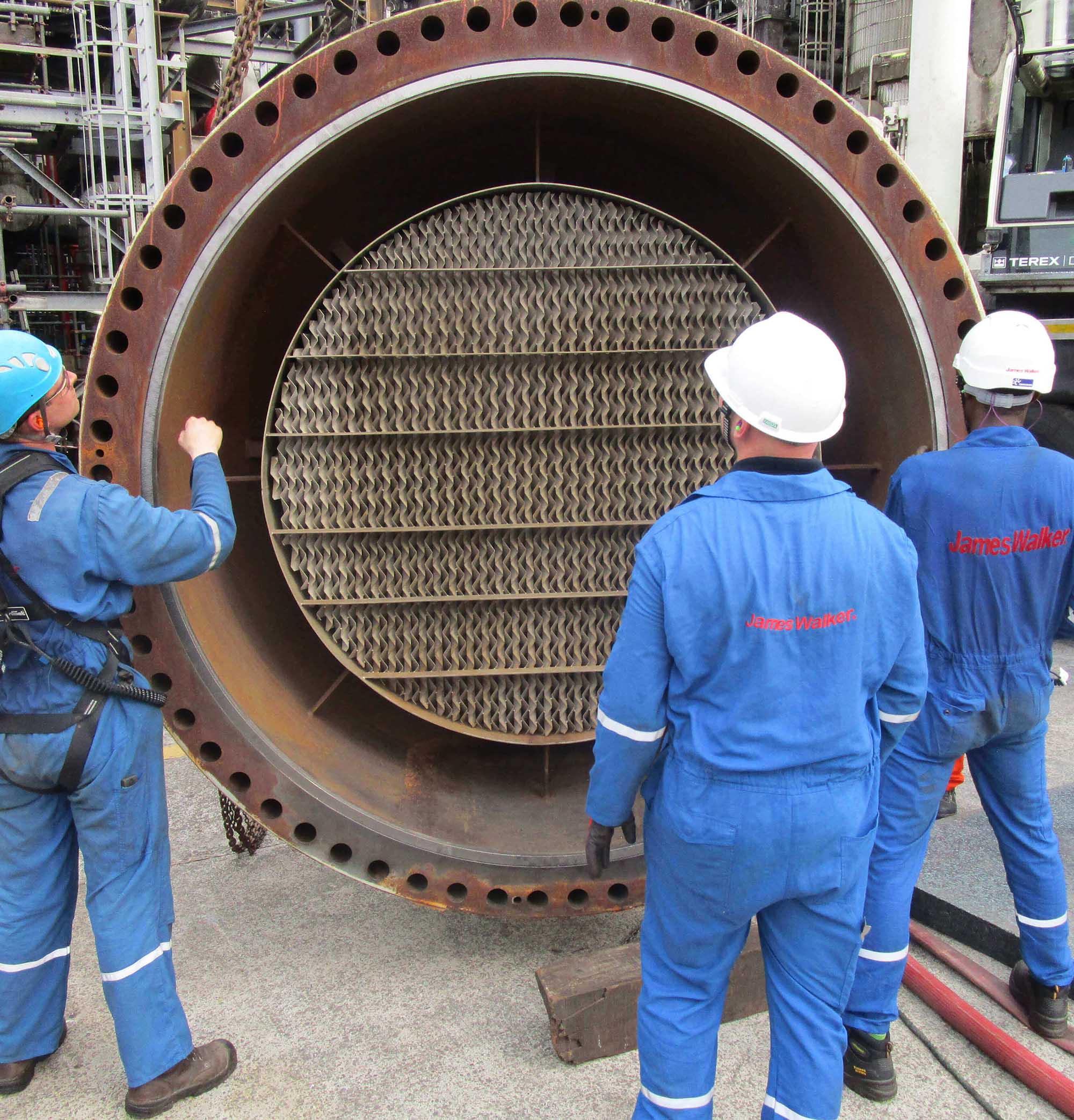

James Walker's Flange Management Services (FMS) team undertook a comprehensive inspection of the tube sheet connections and identified multiple issues requiring attention. These issues included flange deformation and insufficiently machined partition grooves. Additionally, the partition groove's levelness was higher than the sealing levelness on the outer diameter of the flange, exacerbating the leakage problem.

Upon completing the necessary flange machining work, the team at James Walker implemented an innovative solution. Two Metakamm ActiVate graphite facing type CK gaskets were installed, accompanied by 24 M20 RotaBolts. The stress applied to the RotaBolts was adjusted based on FMS calculations, exceeding the levels set with the previous standard kammprofile gasket.

The implementation of James Walker's solution yielded remarkable results. The U-tube heat exchanger underwent a successful and leak-free start-up, maintaining leak tightness even after numerous thermal cycles. This achievement translated into significant improvements in health and safety for the customer. By preventing highly dangerous leaks from critical heat exchangers, James Walker's solution effectively mitigated potential hazards and enhanced the overall safety of the plant and its operators.

The collaboration between James Walker and the customer showcases how a tailored approach to sealing solutions can lead to substantial improvements in safety and operational performance. By addressing the root causes of recurring hot oil leakages and providing an innovative sealing solution, James Walker successfully contributed to a safer and more efficient operating environment for the customer.