You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

We supply a wide range of custom products and materials into a number of different markets and industries globally.

Each of our parts are custom designed for unique applications. Whether you need weight-saving on large components to improve manual handling or installation, or if your challenge relates to corrosion and wear resistance, our experts will be happy to investigate and work with you to find a solution.

These are some examples of components that are regularly requested and are proven in application to offer significant benefits and cover industries such as:

If you don't see your industry or application listed here, please contact us for further advice and information.

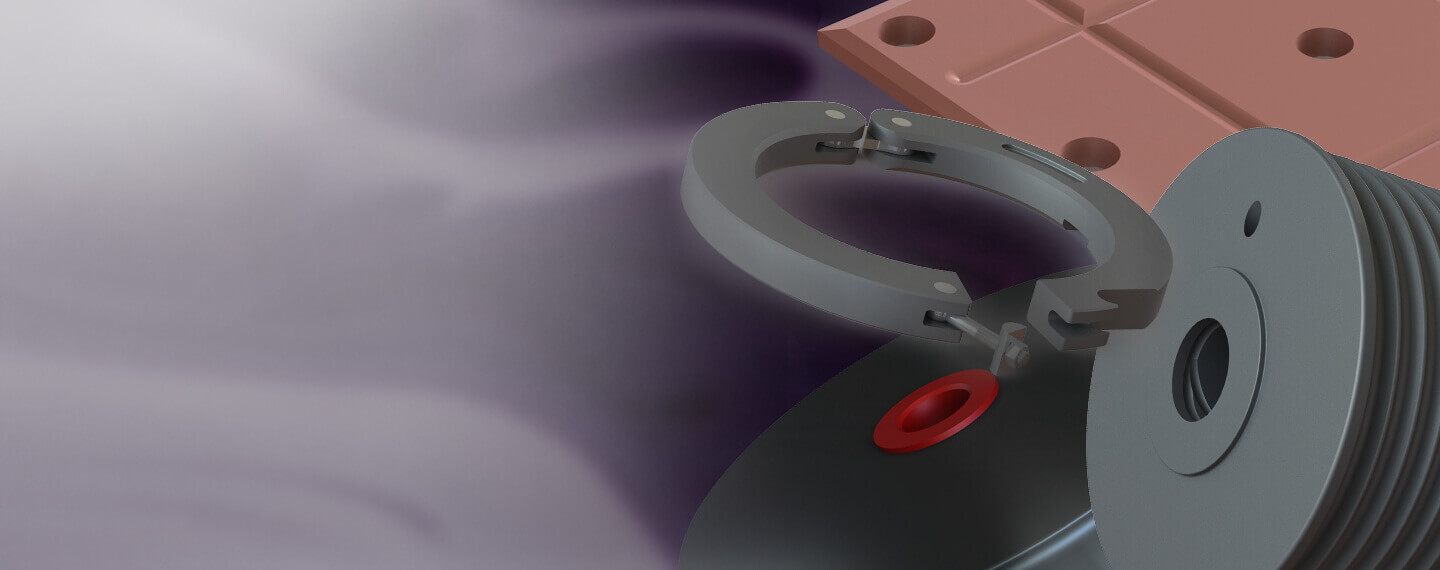

Designed for and manufactured in Devlon; our thrust collars offer a lightweight yet strong and highly durable solution for metal thrust collar replacement.

Our proven two and three-piece designs can be modified to suit any existing space and configuration, and have proven to be a cost-effective way of reducing maintenance time and improving health and safety through ease of handling and assembly.

James Walker has a wealth of experience in the design and supply of thrust collars to customers around the globe. Leveraging the superior mechanical properties of Devlon materials, including high compressive strength plus impact and abrasion resistance, we are confident of being able to offer a product that will provide excellent longevity and performance in service.

James Walker has been pioneering the use of Devlon sheaves in industry for the last 30 years. During this time, we have gained a breadth of experience in the capabilities of our proprietary range of materials, leading us to supply wire rope sheaves across various industries, most prominently offshore oil and gas.

Produced in the same sizes as their metallic counterparts, Devlon sheaves can also be used for similar rope tensions and in many installations have actually resulted in substantially increased periods of service life.

Typical applications:

Benefits of Devlon sheaves:

Wear plates perform a vital role in accurately maintaining the position of the roll chock whilst still enabling ease of adjustment to suit the various material gauges produced.

To ensure product quality is maintained and longevity in service is achieved, it is essential that the materials from which these parts are made have a high load capacity and abrasion resistance.

James Walker offers these components in three materials, each application being reviewed independently to ensure the most appropriate material and design is chosen to optimise ease of fitting and service longevity.

Devlon support rollers have been supplied by James Walker with great success into numerous industries and applications around the world for many years. Drawing on this breadth of experience and knowledge of both the product and its typical applications, James Walker is able to offer an accurate evaluation of any given application and advise on the best Devlon material grade to suit the specific conditions.

With very low weight compared to metal equivalents, Devlon materials present an attractive prospect offering a number of key benefits including high durability and wear resistance, lower noise in operation and lower wear rates to mating surfaces/products, all without any compromise on function.

In metallurgical applications, tasked with transferring the drive load to the mill, bearing slipper pads must withstand sustained friction and high loads.

Commonly used brass or equivalent soft metal bearings are prone to stress cracking, leading to increased downtime. They are both costly and difficult to replace due to their weight, which also creates potential health and safety risks.

At approximately 1/7th the weight of the equivalent product in brass, Devlon materials offer much easier handling without detriment to performance and service lifetime. Where deemed appropriate, James Walker can review the specifics of a given application and, comparing to known pressure / velocity limits, advise on material suitability.

Commonly found in large vehicles and lifting equipment, bushes and bearings are traditionally manufactured from bronze, steel or thermoset / laminate materials.

Typical applications

Benefits of Devlon bushes and bearings:

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.