You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

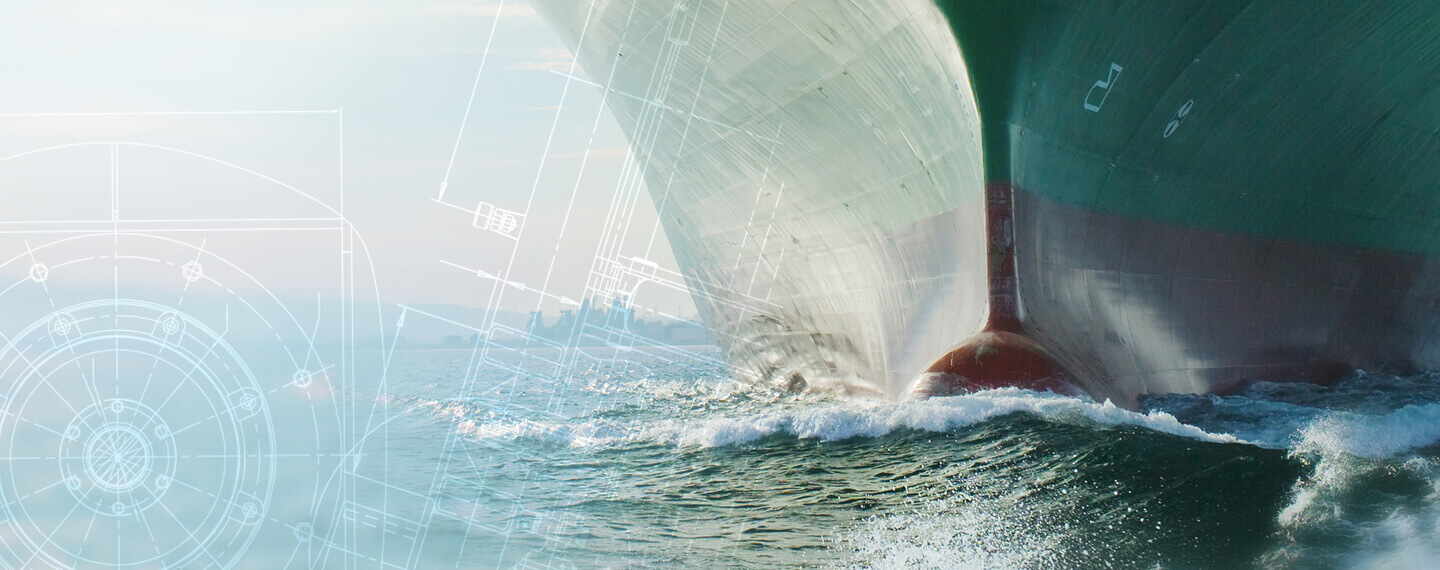

The introduction of regulations requiring vessels sailing in US waters to use Environmentally Acceptable Lubricants (EAL) on all applications where leakage to the environment is possible. However, EAL media degrades over time and its chemistry changes, which can have a significant impact on elastomer seal materials.

This meant that the existing NBR seals on rudders were no longer suitable, but the move to an EAL compatible polyurethane material was proving too cost prohibitive and the customer was seeking a more cost effective way to move to an EAL compatible solution.

Semi-static application

Polyurethane seals

The Walkersele NM86/80LF elastomeric radial lip seal that was offered allowed for seawater lubrication. The solution allowed for EALs to be removed completely from the application which as result removed the associated higher cost of compatible materials and the EAL lubricants themselves.

The low friction material was put in place and trialled successfully, surpassing all expectations on sealing performance. This product also fitted the existing housing with no modifications necessary, offering the additional benefit of a reduced downtime solution.

As it allowed the bearing to be lubricated by seawater, this solution provided the ultimate in environmentally friendly operation.

Our NM86/80LF material helped the customer avoid expensive lubricant costs, as the material meant that they could use seawater to lubricate the bearings. As such, any leakage would not be harmful to the environment.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.