You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

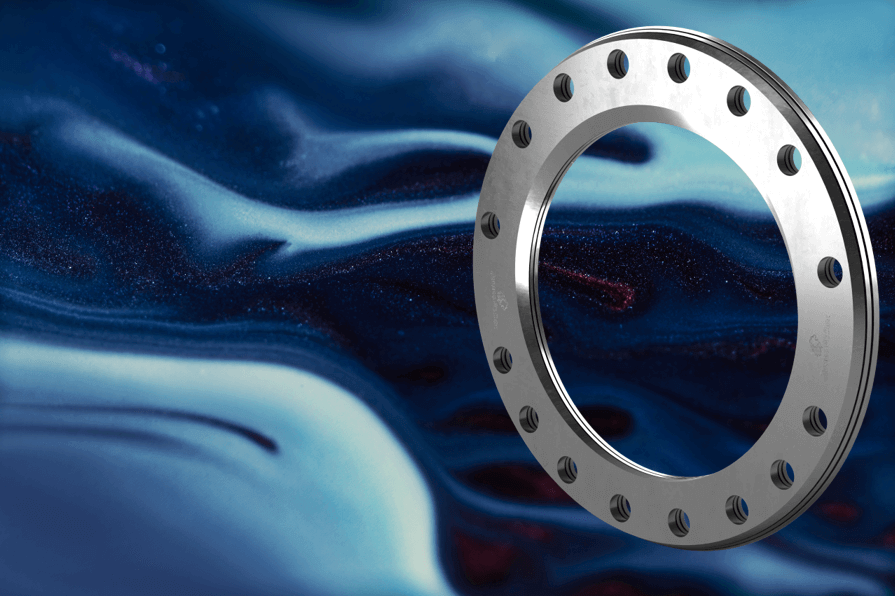

Laminar gaskets ‑ precision machined seals for offset butterfly valve applications

James Walker’s laminar seal is designed for critical service applications in double and triple offset butterfly valves. Manufactured from bespoke metal and filler laminates these laminar gaskets are machined to customer specification providing a precision seal against rigid valve seats, delivering long life even at high cycle frequencies.

Modern butterfly valves are frequently used as cut-off and regulating fittings in many high-temperature / high-pressure applications. One of the serious challenges in this type of applications is the internal sealing of the disc. On the one hand the seal should remain flexible, but on the other, should also be resistant to erosion and wear resulting from the conditions of its use. Often the basic soft sealing materials (elastomers, PTFE) do not fulfil these requirements due to their rapid ageing in higher temperatures; their wear reducing the life of the seal and the periods between maintenance.

The solution to these issues lies in the development of precision-machined laminated offset seals which offer resistance to erosion and withstand higher working temperatures, pressure and cycle rates, guaranteeing a longer life for the entire valve. The most popular form of these seals is a graphite-metal laminated structure constructed of alternate layers of expanded graphite foil (specified for each application for quality, thickness and density) and inter-layers of flat metal elements. The final geometry and material characteristics of each laminar seal are determined by the valve manufacturer and bespoke to each valve.

These are bespoke precision seals manufactured to match the designs of individual double offset and triple offset butterfly valves most commonly for high pressure / high temperature applications;

Graphite laminate

Maximum Temperature:

+450°C (+842°F)

Minimum Temperature:

Cryogenic

PTFE laminate

Maximum Temperature:

+260°C (+500°F)

Minimum Temperature:

Cryogenic

Mica laminate (Consult James Walker )

Maximum Temperature:

+1000°C (+1832°F)

Minimum Temperature:

Ambient

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.