You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

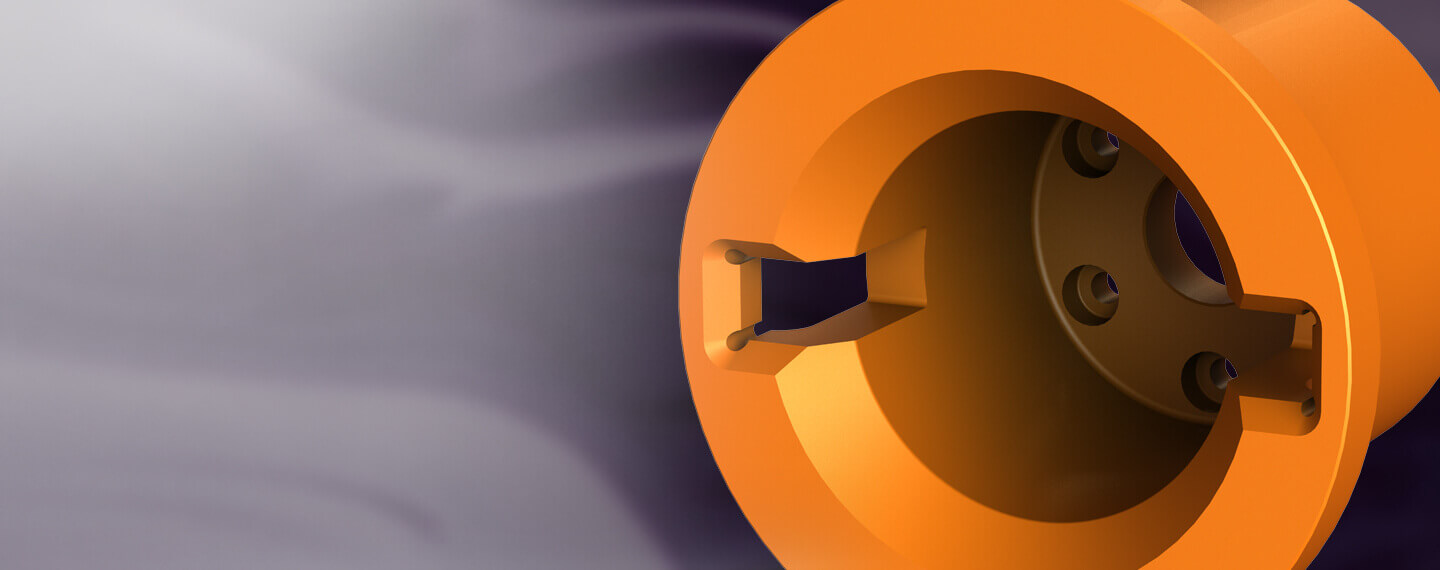

Devlon ROV buckets, manufactured in Devlon V‑API, provide docking, torque reaction, alignment and socket mating for ROV deployed rotary tools and connectors.

We have been serving high performance engineered thermoplastics to the oil and gas industry for over 30 years, with our Devlon materials light-weight for ease of handling and installation and offering long operational life and reduced maintenance requirements in many applications.

ROV buckets are commonly fitted in applications including:

We manufacture two main Class 4 bucket designs as standard, with a variety of mounting configurations available. Alternatively, we can also assist in the design, manufacture and testing of customer-specific requirements.

To fully appreciate the significant weight saving opportunities offered by Devlon ROV buckets, check out this case study. In addition, the following table compares the weight of our standard square-faced design manufactured in Devlon V-API with the most common metal alternatives:

| GR43 steel | Titanium | Aluminium | Devlon V-API | |

|---|---|---|---|---|

| Weight in air (kg) | 30.5 | 17.6 | 10.97 | 4.46 |

| Weight in sea water (kg) | 26.5 | 13.6 | 6.97 | 0.46 |

As part of our rigorous product development programme, our two standard bucket designs were tested to BS EN ISO 13628-8:2006 (incorporating elements from API-17D and API-17H).

Highlights:

The following tests were carried out in line with BS EN ISO 13628-8:2006:

In addition, James Walker also carried out:

In addition to manufacturing a range of associated ROV products to standard or custom designs, we also offer development, testing and manufacture of bespoke components and sub-assemblies to customer specifications. This includes, but is not limited to:

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.