You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

Industry recognised testing highlights the significance of the risk posed by RGD failure and the importance in selecting a material that will meet the most challenging requirements.

Sunday, 6 March 2022Rapid gas decompression resistance is an important consideration for elastomers (and plastics) exposed to arduous conditions commonly found in the Oil & Gas industry. It is critical to understand the combined effects of media, temperature, seal size and the service environment to assess the level of RGD risk. Standardised testing programs allow different materials to be compared and evaluated with results based on the level of damage observed. Testing regimes are not always representative of real world conditions, but high scoring materials tested in challenging environments provide confidence and peace of mind for specifying engineers.

The Norsok standard allows comparison between elastomers but does not fully represent real life situations. NORSOK M710 / ISO 23936-2 makes allowances for nonstandard, bespoke or customised testing programs to be undertaken while using the same scoring to evaluate the results. This provides for variations in pressure, temperature media, section size, number of decompressions and sealing properties to understand and challenge the elastomers RGD resistant capabilities providing greater insight and confidence when selecting materials for difficult service conditions. Bespoke tests with different values for these factors will give greater insight into the most suitable elastomer materials for a given service.

Other standards are also used across the Oil & Gas industry including SHELL MESC 85/301 and Total FINA, GS EP PVV 154/155. These highlight the significance of the risk posed by RGD failure and the importance in selecting a material that meet the most challenging requirements.

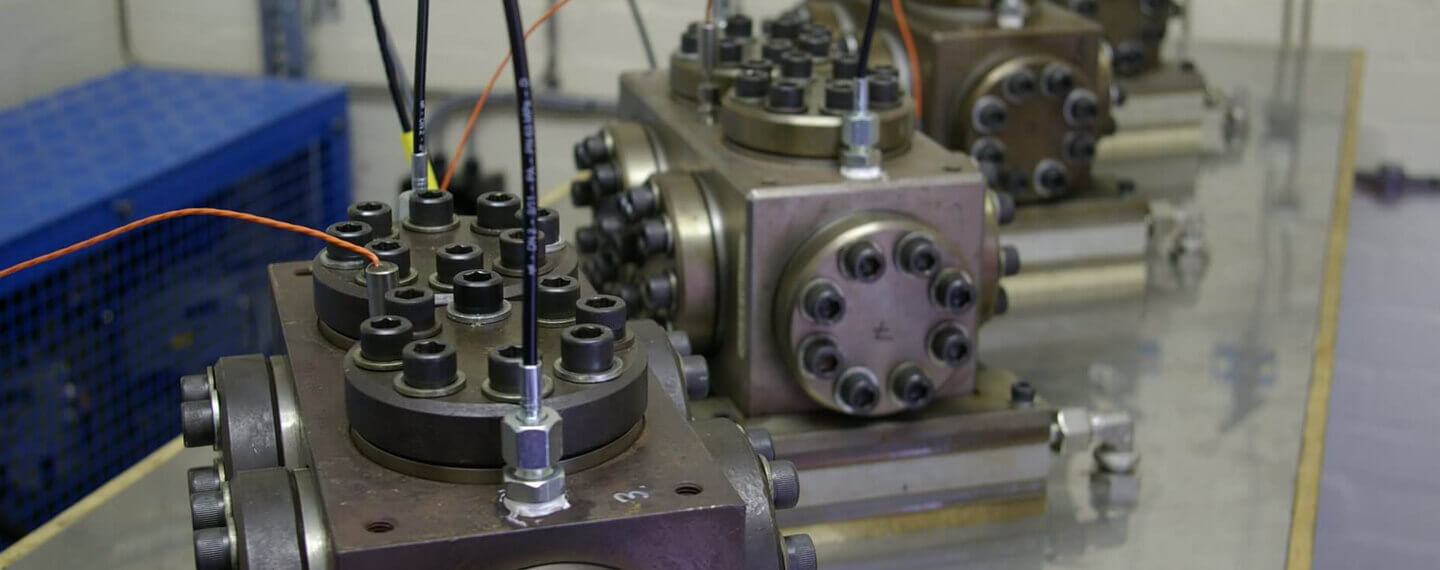

The picture above shows setting up RGD testing rigs at the James Walker material engineering centre.

James Walker has world class facilities for carrying out bespoke RGD testing and has extensive experience in manufacturing RGD elastomer materials. As a result we have a range of elastomers for the Oil and Gas industry that have undergone extensive evaluation using both the standard conditions described in NORSOK M710 / ISO 23936-2, but also in more challenging testing with larger section sizes and diameters, elevated temperatures, and in high CO2 environments. This has provided extensive data and insight in to the performance of elastomers used in Oil and Gas environments, and can be used to confidentially select the most capable materials.

Although RGD excellent resistance can be the difference between success and failure in service, it is not the only performance characteristic that needs to be considered when selecting an elastomer seal. Pressure, chemical interaction, high and low temperature capability, and physical properties as well as the seal profile and housing geometry are among a wide array of properties that require careful evaluation.

James Walker’s engineers and material technologists have extensive experience and are able to discuss your specific requirements to help identify the most appropriate solution. Contact us now to start talking ‘expert to expert’ on this subject.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.