You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

What is RGD and why is resistance to this phenomenon so critical to many sealing applications in the oil and gas industry?

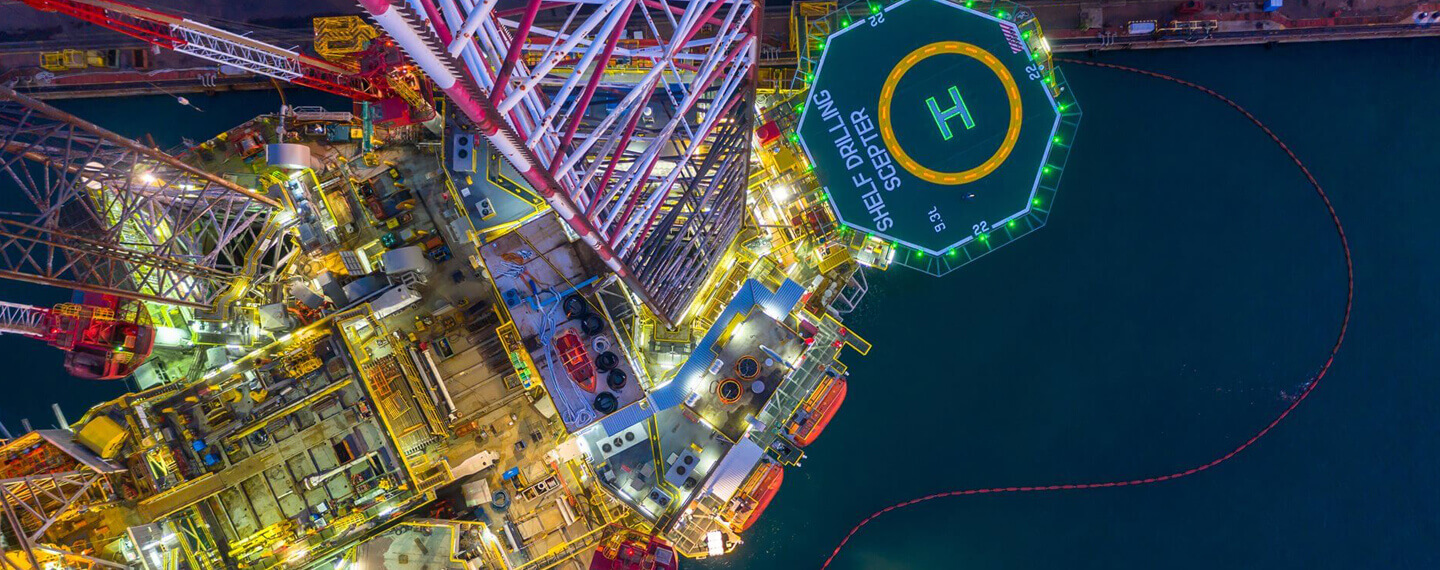

Thursday, 10 February 2022Rapid Gas decompression (RGD) resistance, also referred to as Explosive Decompression (ED) resistance or Anti Explosive Decompression (AED), is a vitally important property of elastomers in the Oil & Gas industry. RGD resistance is a required property for seals operating in the challenging environments found in many in valves, wellheads, trees, manifolds, tubing hangers and other offshore, subsea, surface and flow line equipment.

What is RGD?

The media in upstream oil and gas applications can be under very high pressures and can be present in liquid and gas phases. Even if the medium is nominally liquid there may be dissolved gases that can cause RGD damage. These gases are absorbed into the elastomer seals over time, until the gases inside the elastomer are at the same pressure as the system. Some swell will result in this absorption but while the system pressure remains high no damage to the elastomer will occur. If the system pressure is quickly released, for example as a result of a blowdown event or the opening of a valve, a pressure difference occurs between the gas trapped in the elastomer seal and the surrounding environment. The gases within the elastomer will expand which can inflate the material causing blistering and cracking. RGD induced damage has the potential to cause catastrophic seal failure.

Note: RGD damage is a physical phenomenon and not due to chemical attack. However, some gases for example H2S, will also chemically attack susceptible elastomers, and must be considered separately and in addition to the potential for RGD damage.

Factors affecting RGD damage

RGD Resistant elastomers

Specialist HNBR, FKM, FFKM and Aflas compounds can be optimised for RGD resistance. In order to achieve RGD resistance the elastomer will typically be a harder grade and have high modulus, but developing elastomers with these properties will not ensure RGD resistance has been achieved. Compounds are carefully designed and processed specifically to achieve RGD resistance, and are then tested to assess and demonstrate they possess the desired RGD resistant characteristics.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.