You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

James Walker can provide support and guidance on traceability throughout the manufacturing process, including on‑site installation and maintenance.

Thursday, 10 February 2022Whilst labelling requirements for seals used in biopharma applications are very detailed (including material type, material grade, batch number, date of manufacture, etc), such information is generally confined to the packaging. Once the seal is removed from the packaging, this information is often lost due to poor, and in some cases no, records of batch and/or date of installation having been documented. In the event of a non-compliance this makes the subsequent investigation very difficult and costly. Methods to retain such information, and maintain full traceability are available and options are detailed below.

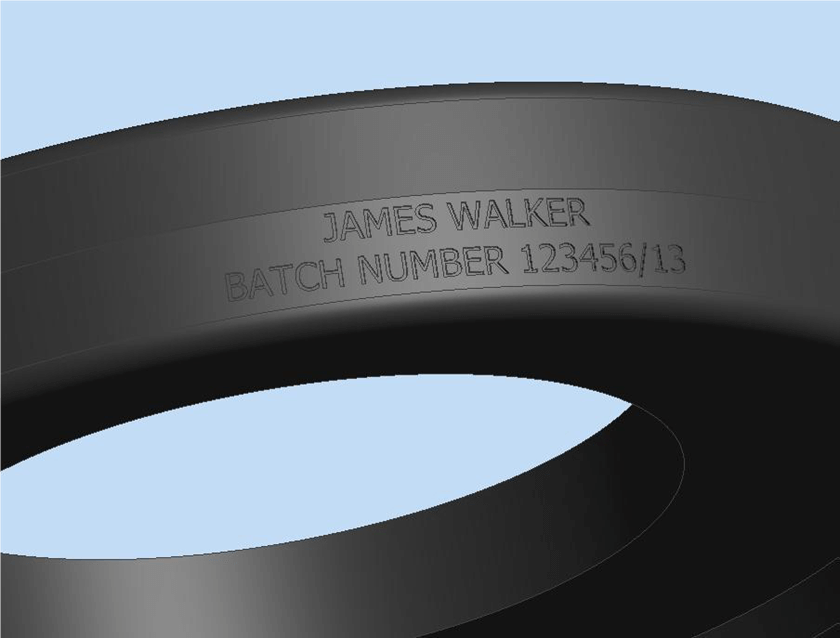

Laser Marking

Laser Marking

James Walker design and mix their own rubber materials and assign a unique batch number to every rubber compound mixed, which follows the material throughout the process, and ultimately on to the packaging. Knowing the batch number of the material gives full traceability of the history of the product manufacture, including moulding and mixing, and indeed back to the individual materials that are combined to give the rubber compound.

James Walker already identify their product by moulding in ’JW’ into each and every part giving some degree of traceability, however, laser marking the batch number on a non-sealing face on the seal gives total traceability. As previously stated, knowledge of the batch number allows access to the entireprocessing history of the seal, making any non-compliance investigations much easier, and subsequently less costly.

Software

Bespoke, proprietary software systems are available that record material type, batch number, seal location as well as any observations on the removed seal (splits, etc.) and ferrule condition (e.g. scratching, pitting, roughing, etc.) for every seal location. Not only does this give full traceability, it also provides useful information to create data-driven maintenance scheduling, therefore optimising performance and minimising downtime.

James Walker can provide support and guidance on traceability throughout the manufacturing process, including on-site installation and maintenance if required.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.