You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

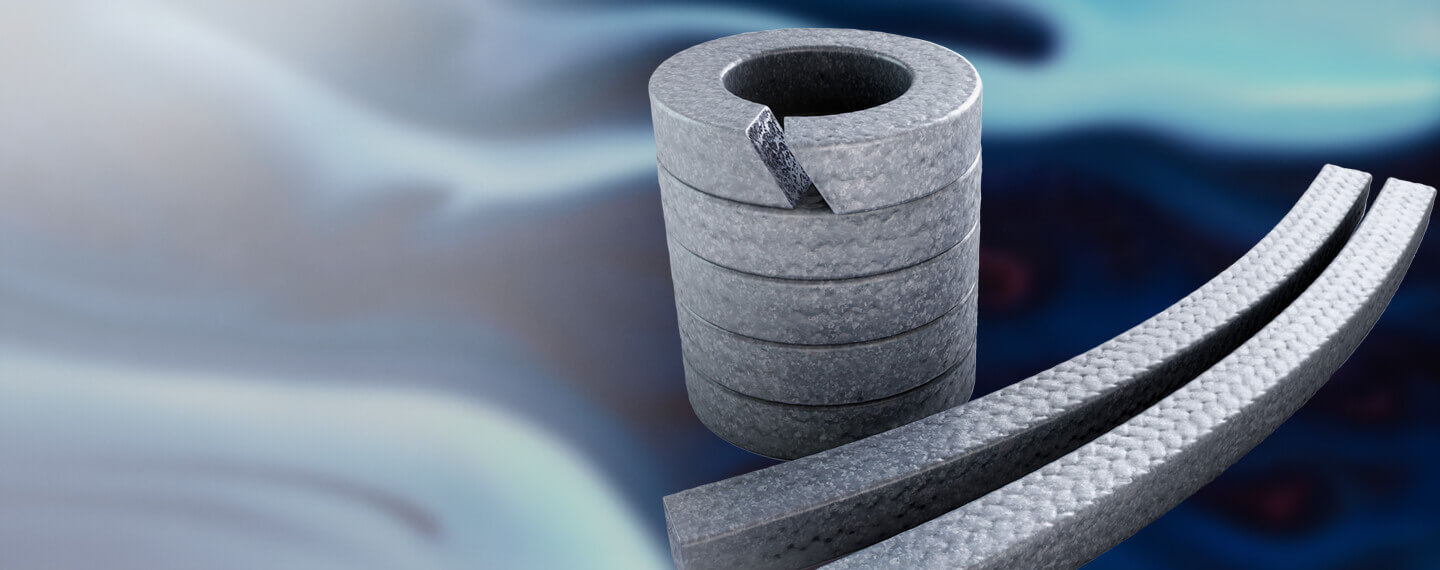

A graphite yarn compression packing designed for valves in oxygen service.

Supagraf OX has been developed specifically for valve services with gaseous and liquid oxygen, to provide safe operation and low emission rates. This valve stem packing is manufactured in a clean room environment, from yarn to finished product. It comprises high purity flexible graphite yarn treated with oxidation inhibitors. The yarns are individually reinforced with Inconel 600 wire mesh.

For gaseous oxygen service up to +60°C (+140°F):

For gaseous oxygen service from +60°C (+140°F) up to +300°C (+572°F):

For liquid oxygen service:

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.