You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

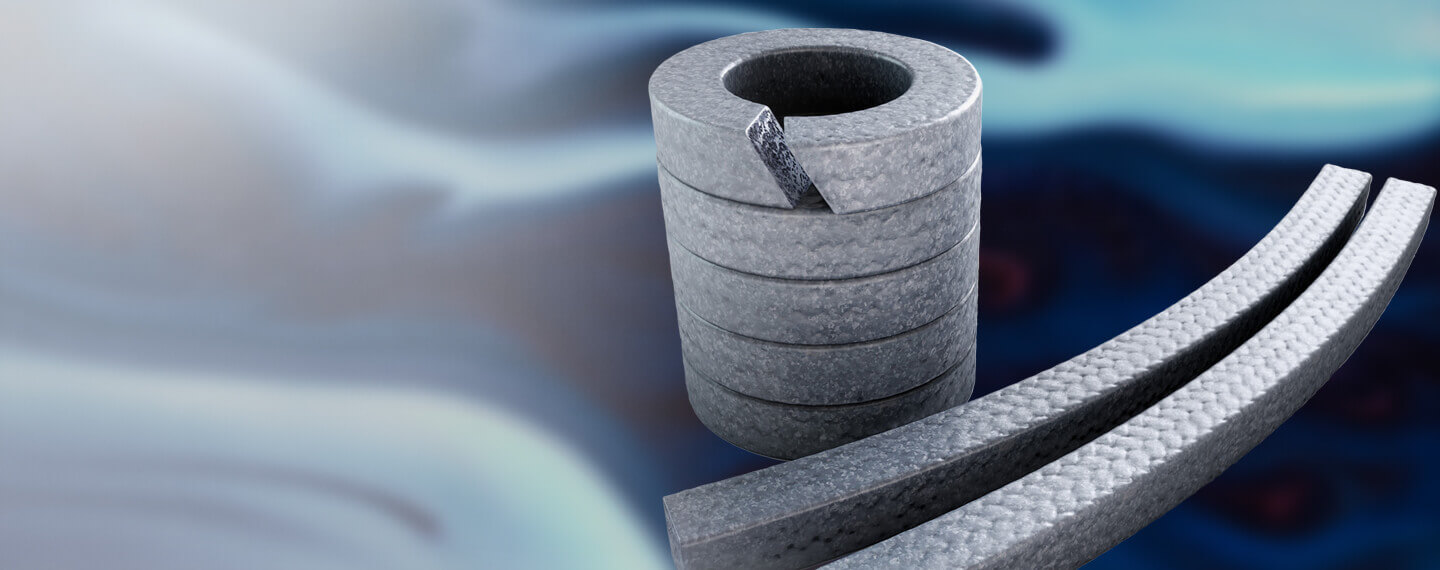

A high performance fugitive emission control packing for valves.

Supagraf FE is third party tested to all known industry standards producing exceptional performance, 8 ppmV average emission level in API 622 3rd edition test with no adjustments. This is a cost effective fully braided packing manufactured in exfoliated high purity 98% graphite, reinforced with Inconel wire to provide additional strength and resistance to pressure and extrusion.

This packing incorporates a new generation cutting-edge lubrication system that not only helps to prevent the pick-up of graphite on valve stems but also provides ultra-low friction performance with advanced corrosion inhibiting properties.

Valve stem duties:

Compatible with media in the range of pH 1-14 excluding strong oxidising agents. The product has negligible volatile content.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.