You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

Suitable for all types of vessel and International Maritime Organisation (IMO) classes.

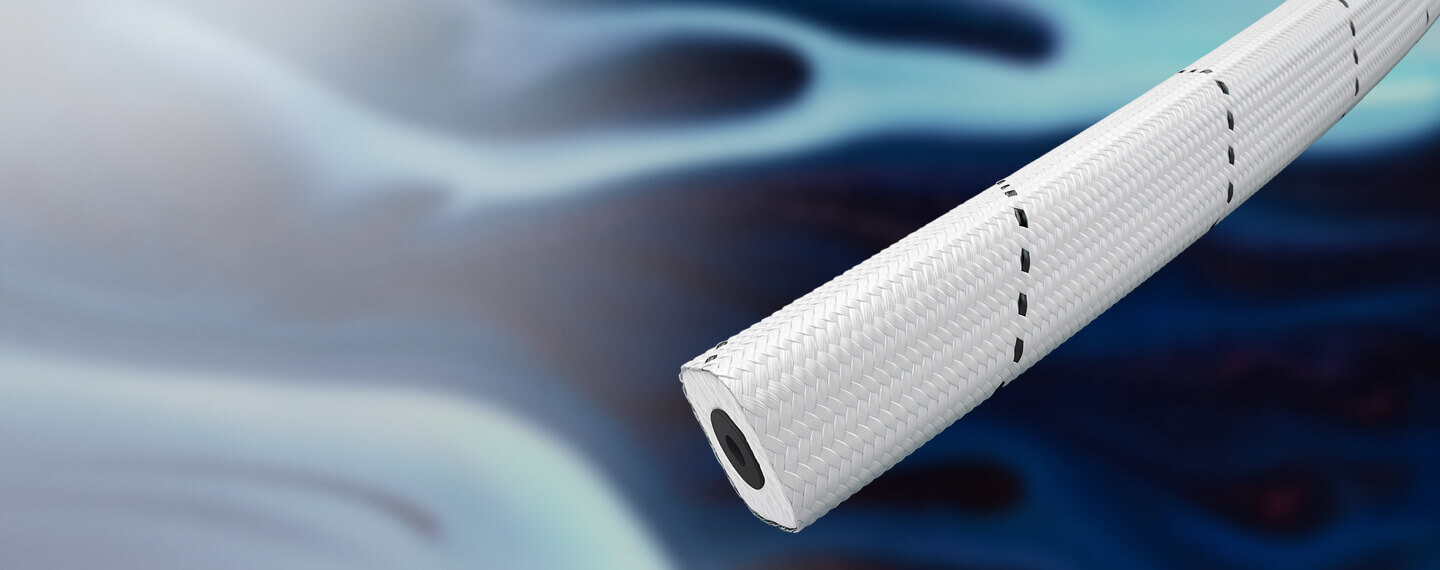

Tankatite 440 is a resilient elastomeric core, spirally wrapped with PTFE tape and surrounded by successive braided jackets of inert polypropylene yarn. Specially reinforced corners are incorporated to build the section to the required packing size.

The braided structure is spirally wrapped with further layers of PTFE tape to provide an impermeable barrier to liquids and gases, then finally enclosed in a robust, abrasion resistant braid of PTFE yarns.

Suitable for bulk liquid cargoes in all International Maritime Organisation (IMO) classes, this product is commonly used in the sealing of tank lids, main hatches, inspection and cleaning covers on tankers and chemical barges.

Static duties on tank lids

Compatible with media in the range of pH 0-14 including all known bulk cargoes in all IMO classes.

Any square or rectangular sections of 12.5 mm (1/2") upwards is made to order, also endless rings to fit specific tank lid recesses.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.