You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

Our compact rod/gland seal and single‑acting piston seal with high and low pressure sealing capabilities.

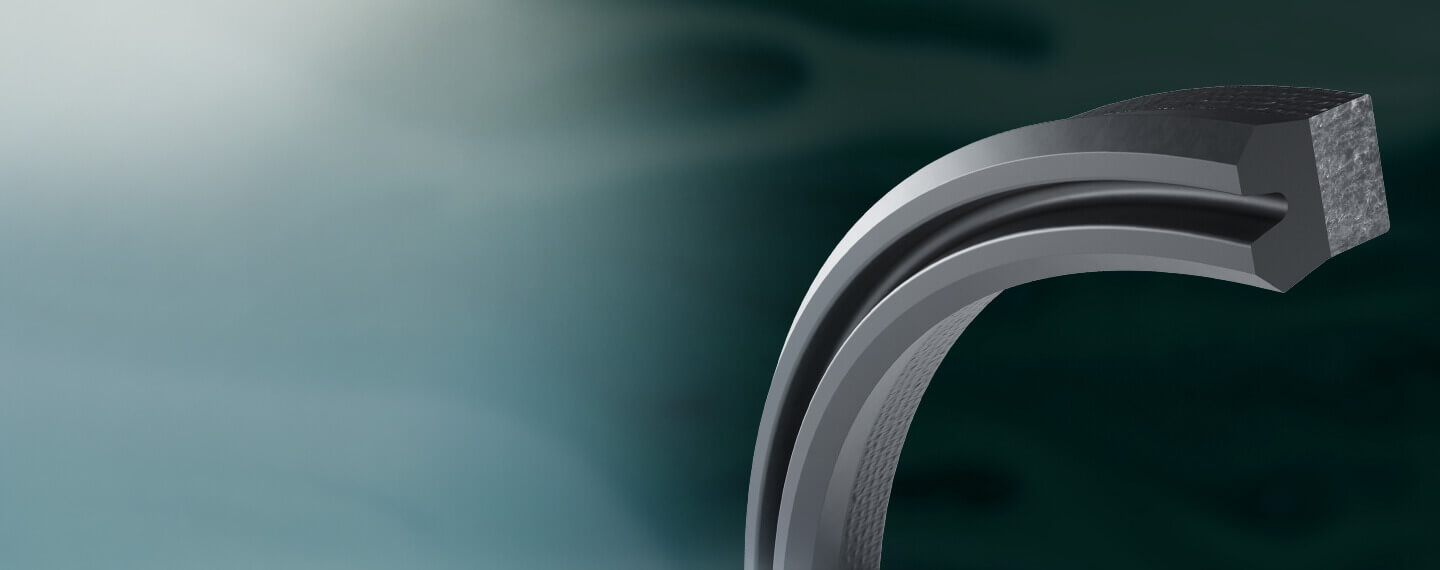

Solosele G is a compact rod/gland seal and single-acting piston seal with excellent high and low pressure sealing capabilities that provides cost savings through reduced housing groove requirements.

It comprises a profiled elastomeric sealing element that is firmly protected by an integral anti-extrusion element of rubber-proofed fabric. High integrity sealing is enhanced by its flexible chamfered lips.

In operation, the elastomeric element provides low-pressure sealing by means of radial squeeze. As pressure increases, the pressure responsive action maintains the sealing force - even when there is significant rod misalignment.

The tough integral fabric/rubber base resists extrusion whilst being sufficiently flexible to allow recess fitting in the majority of cases.

Solosele G-AE is available with separate triangular base ring (external or internal) of PTFE, nylon or acetal to reduce friction or limit seal contact area on short-stroke applications. Dependent on whether the seal is used in a rod/gland or piston sealing application, the seal base ID or OD corner has a moulded chamfer recess in which the split anti-extrusion element/ring is positioned.

Odd-legged design is available to prevent excessive axial movement within the housing. This prevents fluid pumping under the seal lip during low-pressure rod retraction.

Rod seal for hydraulic cylinders; ram seal for hydraulic presses; or single-acting piston seal. (Two seals can be used for double-acting piston duties, but care must be taken to relieve any potential inter-seal pressure build up).

It is also suitable for slow semi-rotary applications including swivels and distributors. Additional duties include turbine blade roots, guide vanes and servo motors on hydroelectric plant - and as a static seal that offers the benefits of an 'O' ring with integral anti-extrusion capability.

Elastomeric sealing element

Anti-extrusion element

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.