You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

Highly proven on industry's most arduous applications.

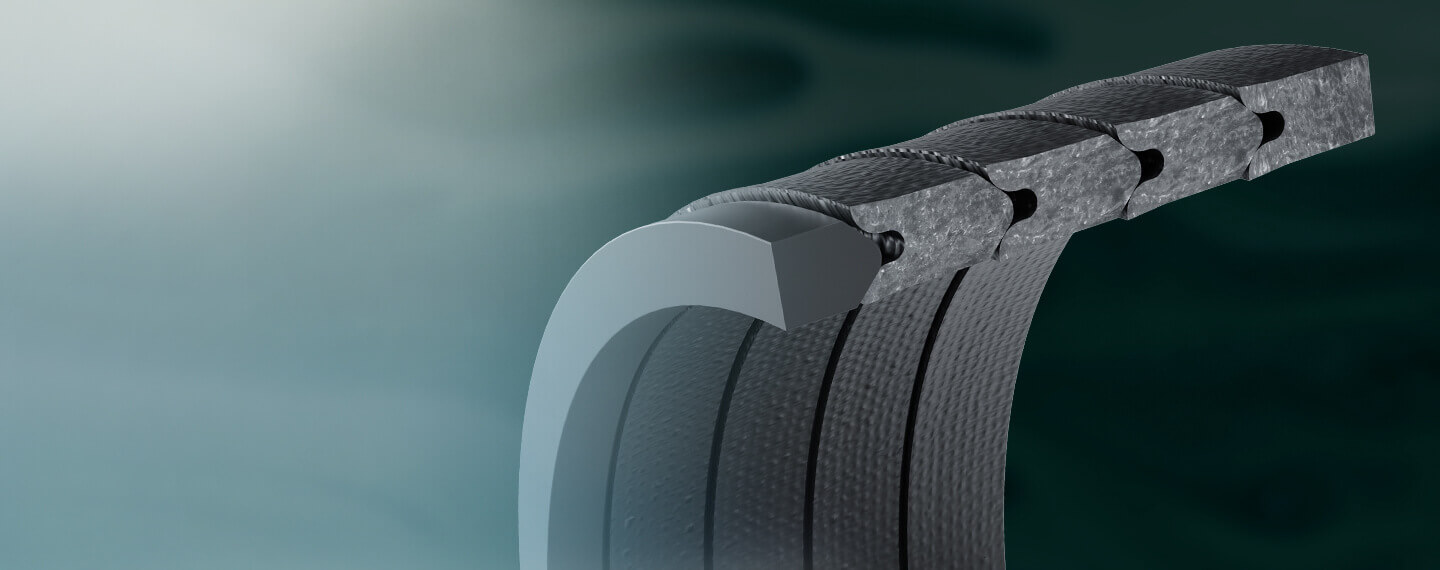

Our Lion expanding packing set is highly proven on industry's most arduous applications. It has a sealing lip profile that is specially developed to withstand the massive side loads and high pressure peaks encountered on forging presses and other large metal-forming plant.

It provides efficient sealing on heavy-duty hydraulic systems and also gives 'bearing' support to the ram, which is particularly beneficial when the ram is horizontal. The 'bearing' role is a very successful feature that relies on the use of deep rings of robust construction to provide radial support to a large ram.

Each Lion expanding set comprises a heavy-duty gland ring/female adapter, two or more intermediate rings, and a header ring. All sealing rings have double lips. A V-shape base on the intermediate rings ensures that the packing responds automatically to system pressure and gives wedging action under gland compression - which helps to keep equipment in service even with worn bushes or rams.

The sealing rings are moulded with an interference fit on the lips to give effective sealing at low pressure, which is augmented when system pressure is applied. The gland ring has a heavily reinforced base to resist extrusion; and individual rings are of very robust proportions to resist distortion under heavy side loads and high-pressure peaks.

A traditional heavy-duty ram seal for forging presses where high side loads and pressure peaks are encountered. Also for horizontal extrusion presses where the sealing rings will help to provide radial support.

Gland ring/female adapter

Intermediate rings

Header ring

Standard materials

Special materials

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.