You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

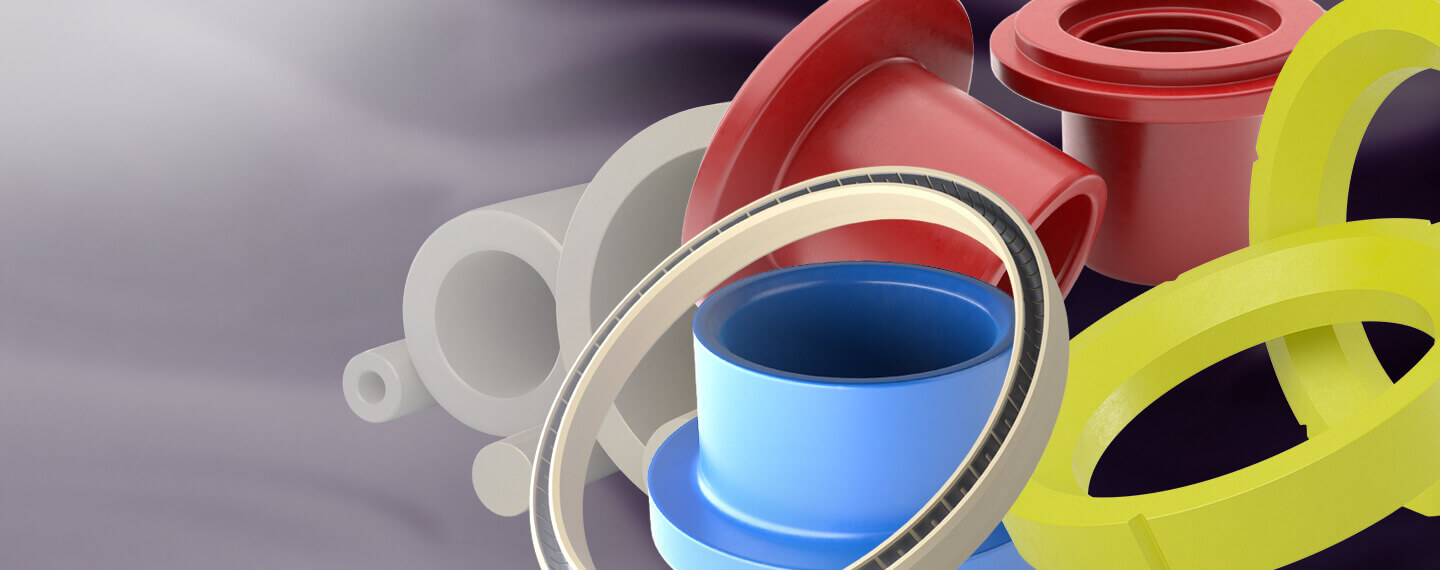

If there is an industrial application requiring specialised engineered thermoplastics then James Walker has a solution.

At James Walker, we strive to offer customers innovative solutions through our vast experience in thermoplastic engineering. We do not simply manufacture components to customer specification - we work in tandem with customers to identify and analyse areas where we think our materials could offer both performance improvements and cost savings.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.