You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

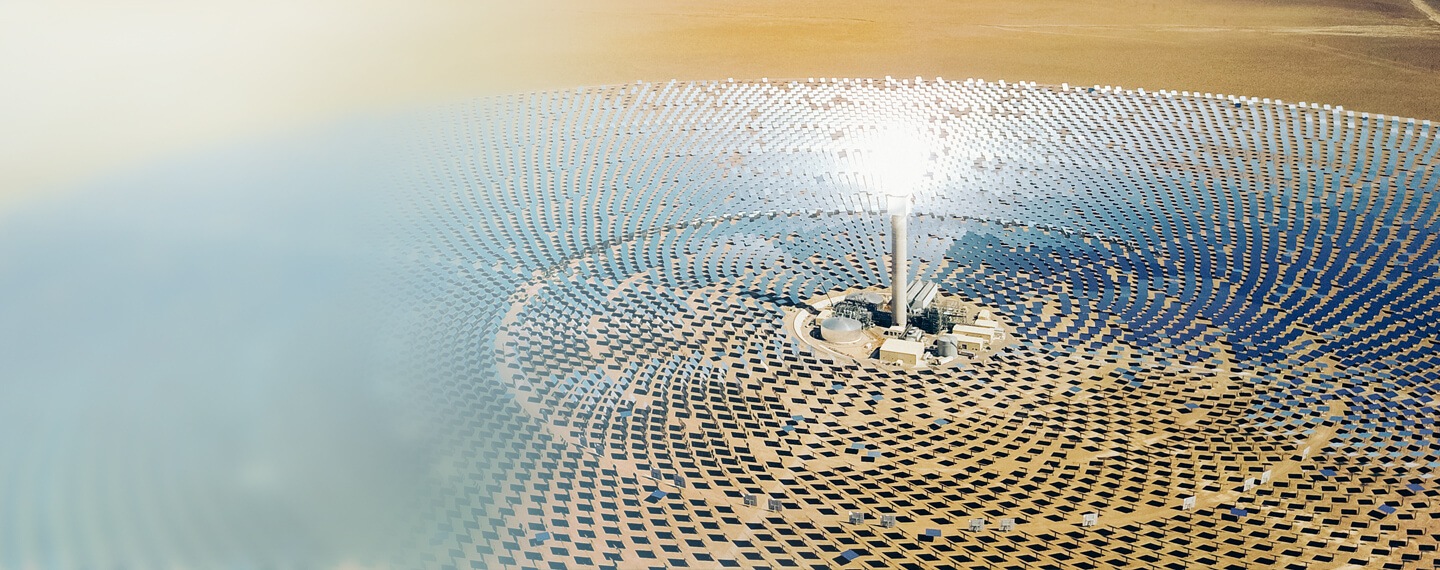

Pump, valve and heat exchanger sealing solutions for molten salt applications in chemical production, nuclear power generation and solar thermal power plants.

Effective sealing of molten salt media

Molten salt media is solid at ambient temperature and pressure but enters the liquid phase when heated. Typically these media are made up of 60% sodium nitrate and 40% potassium nitrate, and melt at around 220°C; although there is a broader variety of molten salts being used with varying melting points. These media are capable of attaining very high temperatures (over 700°C), have an excellent capacity for heat transfer and are also capable of conducting electricity.

The use of molten salts in industrial processes is continually increasing and these media have a variety of uses i.e. batteries, baths for various alloy heat treatments & can also be used as a heat transfer media for efficient thermal storage

The molten salt environment typically involves ultra-high temperatures combined with thermal cycling conditions and chemically aggressive, corrosive and abrasive media – particularly when salt starts to solidify. These are some of the most demanding operating conditions faced by valves and other process equipment.

James Walker has developed a range of high temperature sealing products designed for high performance sealing under such harsh conditions.

When selecting products for specific application, please review each product’s capabilities against the specific working conditions of your application or provide the details to your local James Walker technical team for suitable product or material selection.

Material and product selection for high temperature molten salt applications

The ability to effectively seal these salts, particularly with respect to service life, health & safety and minimised down time, is an important factor that can make a significant contribution to overall process efficiency & in some cases viability.

Users of this media typically experience short seal and component life, particularly where there is any leakage. These leaks require considerable time to clean up and remedy, creating high refurbishment & maintenance costs and impacting overall plant operational efficiency due to unscheduled downtime. In addition they also present a significant health and safety hazard.

The highly corrosive nature of molten salts requires sealing solutions that have excellent chemical resistance, whilst maintaining resilience against the abrasive nature of the media when cooled. Other essential characteristics are thermal stability and resilience to relaxation to ensure a sealing product has excellent high temperature performance plus a capability to withstand aggressive thermal cycling common for this application.

Testing, field trials and operational performance of James Walker products in molten salt applications have shown our solutions providing multiple benefits to our customers, most significantly in terms of reducing maintenance requirements, the resulting improvement in productivity and efficiency all backed up with the enhanced health and safety on site that comes from eliminating leakages.

When selecting products for specific application, please review each product’s capabilities against the specific working conditions of your application or provide the details to your local James Walker technical team for suitable product selection.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.