You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

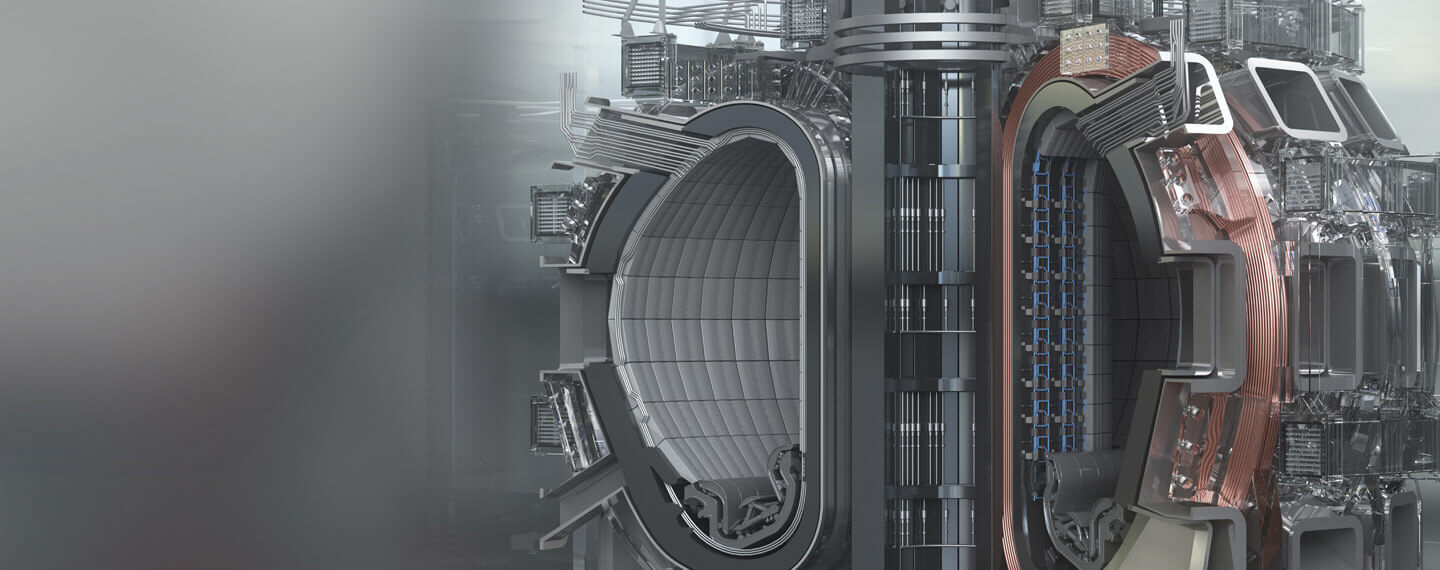

James Walker holds a respected reputation as a leading force in the application of materials technology to provide effective solutions to operational issues in critical nuclear applications.

Based on our unrivalled experience, we precisely match materials, product design and component manufacturing methods to meet customers' exact specifications and operational requirements.

With over 40 years of service to the nuclear sector, our materials and products are used across a broad range of applications including:

Supplying only the highest integrity materials and specialised fluid sealing products to the nuclear industry, our capabilities are firmly based on our knowledge of the processes involved, their highly specialised sealing requirements, plus the need for exacting quality control and assurance regimes.

We are at the forefront of development and application of high performance elastomers. In addition to working with industry standard materials and customers' own proprietary materials, our materials technology centre is continually working on new formulations to meet customer specific operational parameters and to advance our own product ranges.

The result is materials for sealing related products that work efficiently and for longer at extremes of temperature and pressure, with improved resistance to chemicals, abrasion, or ionising radiation.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.