You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

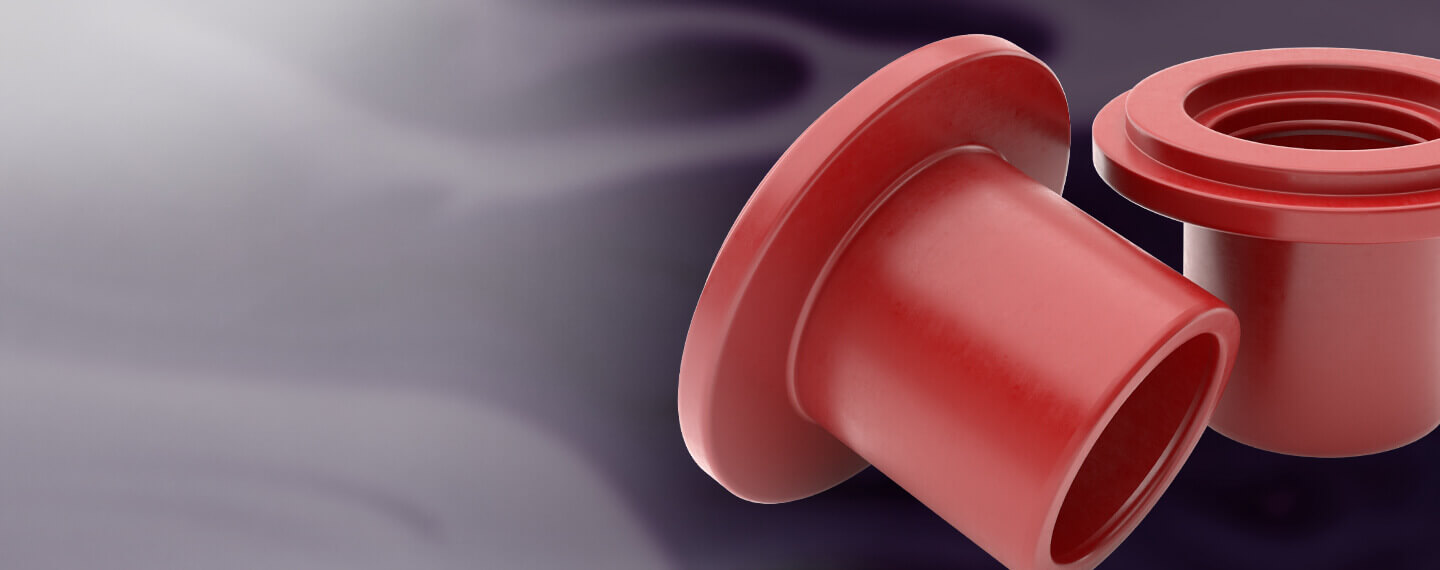

A self‑lubricating polyamide‑based material for dry running applications.

Devlon Devlube is specifically designed for dry running applications where low friction is required and normal lubrication is not possible.

A polyamide-based material, Devlube is self-lubricating. Reduced wear through lower friction means excellent retention of physical properties and very little maintenance for components manufactured in this material.

Suitable for a wide range of dynamic applications, common components include bearing blocks, wear pads, cam followers, conveyor components and worm screws.

Devlon Devlube is suitable for a wide range of dynamic applications, common components include bearing blocks, wear pads, cam followers, conveyor components and worm screws.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.