You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

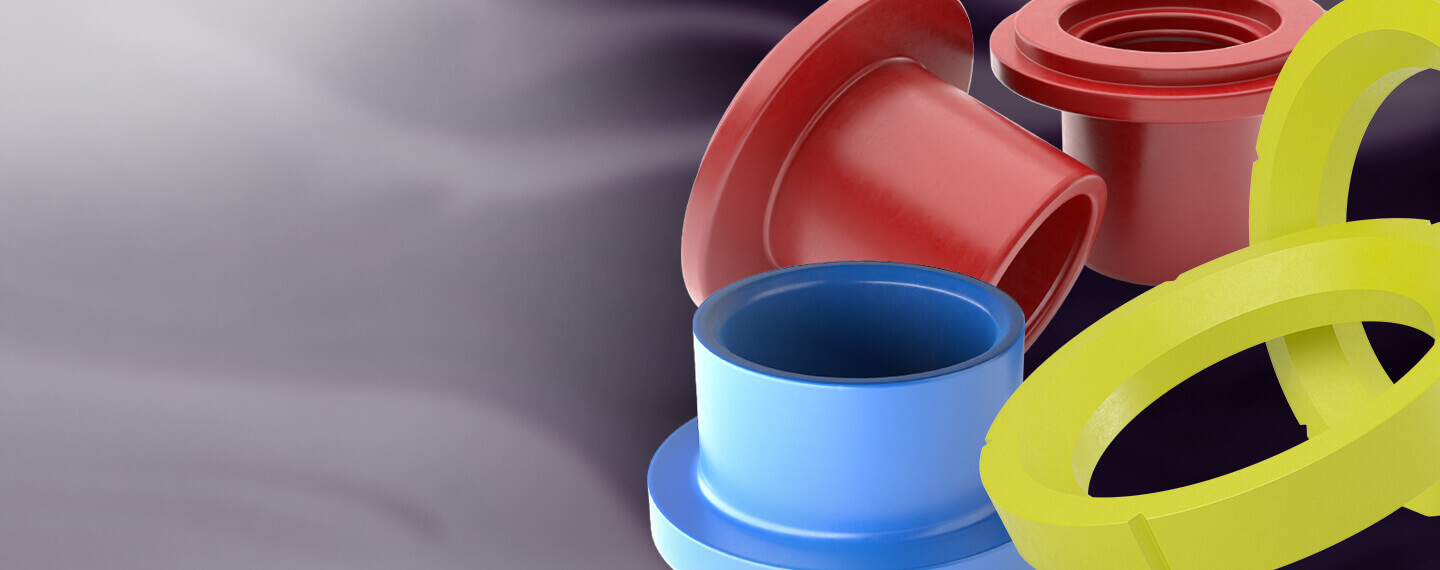

Our proprietary high‑specification engineered thermoplastics, used across a wide range of industries and renowned for their outstanding properties.

Our Devlon materials consist of a range of specially formulated engineered thermoplastics and they are amongst the toughest and hardest wearing available. Produced by monomer casting, they provide a comprehensive range of wear resistance, impact strength and moisture absorption properties. We produce complex components in Devlon ranging from 10 mm to over 2500 mm OD, and weighing up to 1000 kg.

Devlon materials offer a wide range of benefits thanks to their mechanical properties, including corrosion resistance, low friction, impact strength and a significant weight reduction in comparison to traditional metallic counterparts.

Devlon is the name given to our range of proprietary high performance thermoplastic materials, developed by James Walker. Each grade has its own distinctive properties for use in critical applications, including our cast polyamides processed in-house to our own unique formulations.

Yes. Like all thermoplastics, Devlon does absorb some moisture. This phenomenon is predictable and providing your parts are toleranced accordingly, they will operate problem-free in this environment.

Initially Devlon components are competitively priced and are often less expensive than the materials they replace. The greatest savings, however, are made by the increased life performance of the parts, protection of mating parts, decrease in service costs and reduction in downtime.

Devlon is slow-burning and self-extinguishes after removal of the flame source. Devlon is UL 94 rated V2. The material has an oxygen index of 24.1 to 27.2 dependant on grade.

Yes. Devlon is resistant up to 10^6 rads. Thereafter some surface degradation occurs which is seen as discolouration and surface cracking.

Although not always necessary, dependant on speeds and loads, greasing or lubricating polymer materials is generally advantageous.

The long-term service temperature is defined as being the maximum temperature at which plastics can be kept in hot air for 10,000 and 20,000 hours without losing more than 50% of the initial values for their typical properties. The short-term service temperatures are the short-term peak temperature values that the plastic can withstand for a period of minutes or sometimes even hours without the plastic being damaged, taking into account the load and its duration.

Copolymer and homopolymer acetals are very similar in many characteristics. However there are some differences - homopolymers tend to have better wear resistance and are better for use in applications with friction and wear problems. Copolymer materials possess better chemical resistance.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.