You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

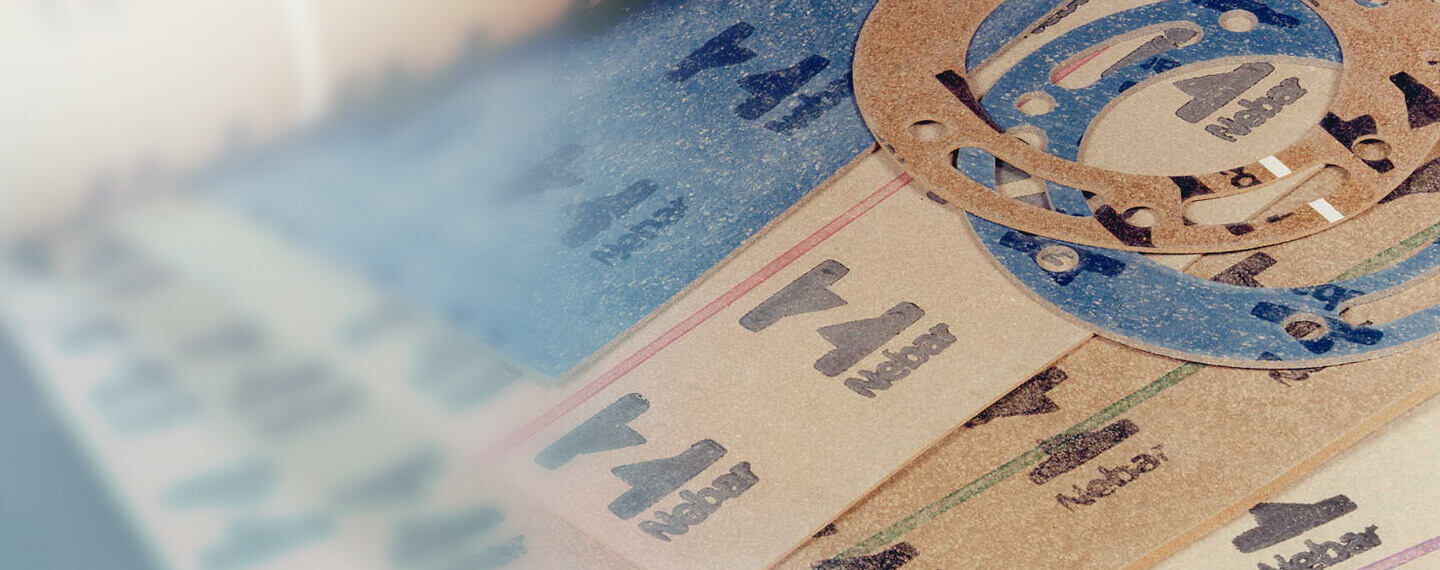

Nebar is our range of rubber‑bonded cork gasket materials designed for sealing flat flanges against fluid leakage.

High grade, general purpose

General purpose, high quality cork-elastomer jointing. Below 3 mm thickness it comprises predominantly nitrile bonded cork; at 3 mm and above the cork is bonded with a polychloroprene / nitrile blend.

Recommended maximum system pressure is 0.5 MPa/5 bar. Consult us for use with higher pressures.

Follow this link to download our data sheet for Nebar Brown

Prime features

Specifications

Fluid compatibilities

Physical properties

<3mm thickness

≥3mm thickness

How supplied

Neoprene electrical grade

Economical, high quality cork-elastomer jointing based on a neoprene/nitrile/SBR blend.

Recommended maximum system pressure is 0.5 MPa/5 bar. Consult us for use with higher pressures.

Follow this link to download our data sheet for Nebar Orange

Prime features

Specifications

Fluid compatibilities

Physical properties

How supplied

Premium neoprene electrical grade

Premium quality cork-elastomer jointing, based predominantly on polychloroprene. Well proven over many years in heavy electrical plant.

Recommended maximum system pressure is 0.5 MPa/5 bar. Consult us first for use with higher pressures.

Follow this link to download our data sheet for Nebar White

Prime features

Specifications

Fluid compatibilities

Physical properties

How supplied

Nitrile electrical grade

High quality, medium-to-hard grade of cork-elastomer jointing based on nitrile elastomer.

This material is able to withstand a higher degree of compression than other grades, which enables it efficiently to seal transformer lids (and other equipment) where flanges suffer a degree of non-parallelism. Moreover, its ability to withstand vapour phase drying removes the need for test gaskets.

Recommended maximum system pressure is 0.5 MPa/5 bar. Consult us first for use with higher pressures.

Follow this link to download our data sheet for Nebar Purple

Prime features

Specifications

Fluid compatibilities

Physical properties

How supplied

For higher pressure duties

A high quality blend of cork and polychloroprene that withstands higher pressures and gasket loading than other Nebar grades, particularly in the electrical industry.

Recommended maximum system pressure is 0.6 MPa/6 bar. Consult us first for use with higher pressures.

Follow this link to download our data sheet for Nebar Red

Prime features

Specifications

Fluid compatibilities

Physical properties

How supplied

Premium nitrile electrical grade

A nitrile based high quality cork-elastomer jointing material providing excellent resistance to a wide range of media and specifically developed to meet the requirements of the Ministry of Defence Specifications BS 2F66 and DEF 22.

Recommended maximum system pressure is 0. 5Mpa/5 bar. Consult us first for use with higher pressures.

Follow this link to download our data sheet for Nebar Yellow

Prime features

BS 2F66 and DEF 22

+110°C maximum operating temperature in liquids

Retains flexibility down to -20°C

Specifications

Fluid compatibilities

Physical properties

How supplied

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.