You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

Texas Tower high temperature channel / shell and channel / channel cover flange connections were failing due to low bolt loads. High temperatures were causing flange rotation and graphite oxidation which in turn were leading to bolt relaxation and leakage.

During our preliminary investigations it was found that bolt loads had not been verified beyond basic torque tightening values on installation. This ultimately lead to the flange catching fire and requiring a steam quenching process to prevent further damage.

Vertical Texas Tower heat exchanger (29 m tall) reducing reactor effluent temperature from 491°C to 115°C.

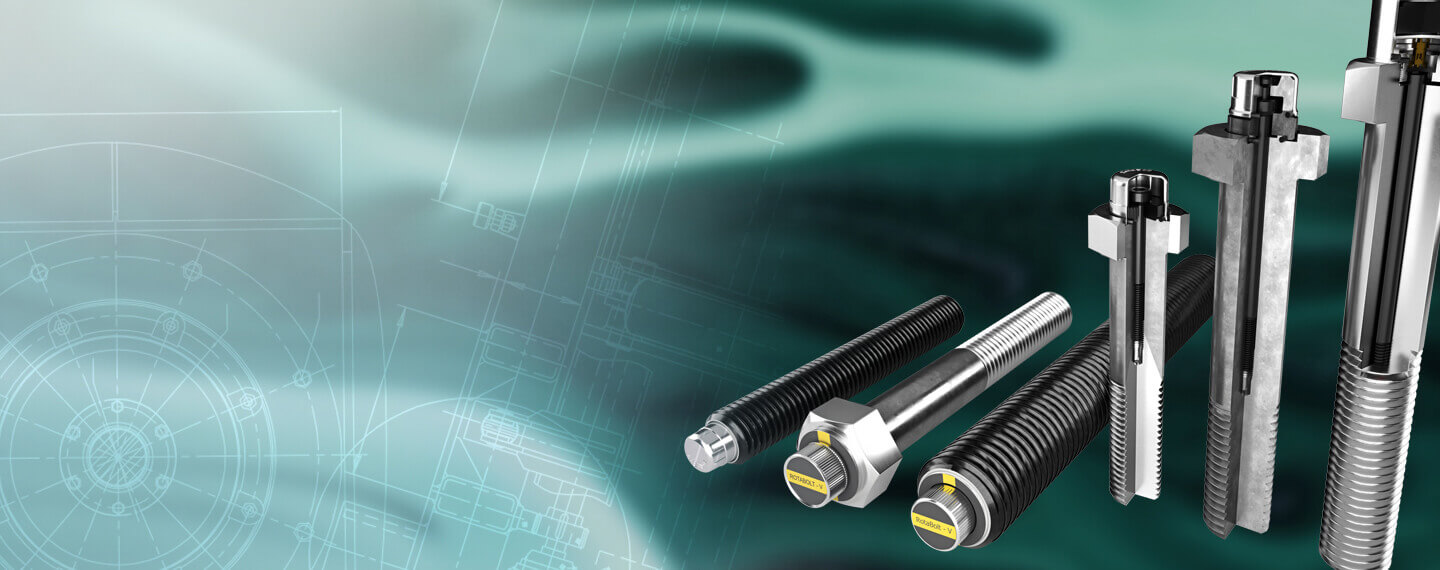

Kammprofile gasket with commercial graphite facing and Inconel 718 studs - bolt stress 360 MPa

We provided calculation support of the optimum bolt load for the joint. From this analysis it became evident the bolt diameter needed to be reduced from from 1 1/8" to 1" by the use of bolt collars. This would reduce the level of flange rotation under elevated temperatures.

Retaining Inconel 718 was advised for bolt material, to maintain better creep resistance at the high operating temperature. Although, these bolts were further supported with RotaBolt technology to ensure all bolts were tightened to the target bolt load.

To reduce the negative impact of graphite oxidation, the kammprofile gaskets were specified with APX-2 and SS321 materials. This reduced graphite oxidation and increased working life for the gasket.

These flanges are back in service with no steam quenching required as the risk of flange leakage and fires has been eliminated. It is expected that these flange connections will now perform leak-free between turnarounds as a result of more accurate bolt tension and extended service life of the critical cover flange gaskets.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.