You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

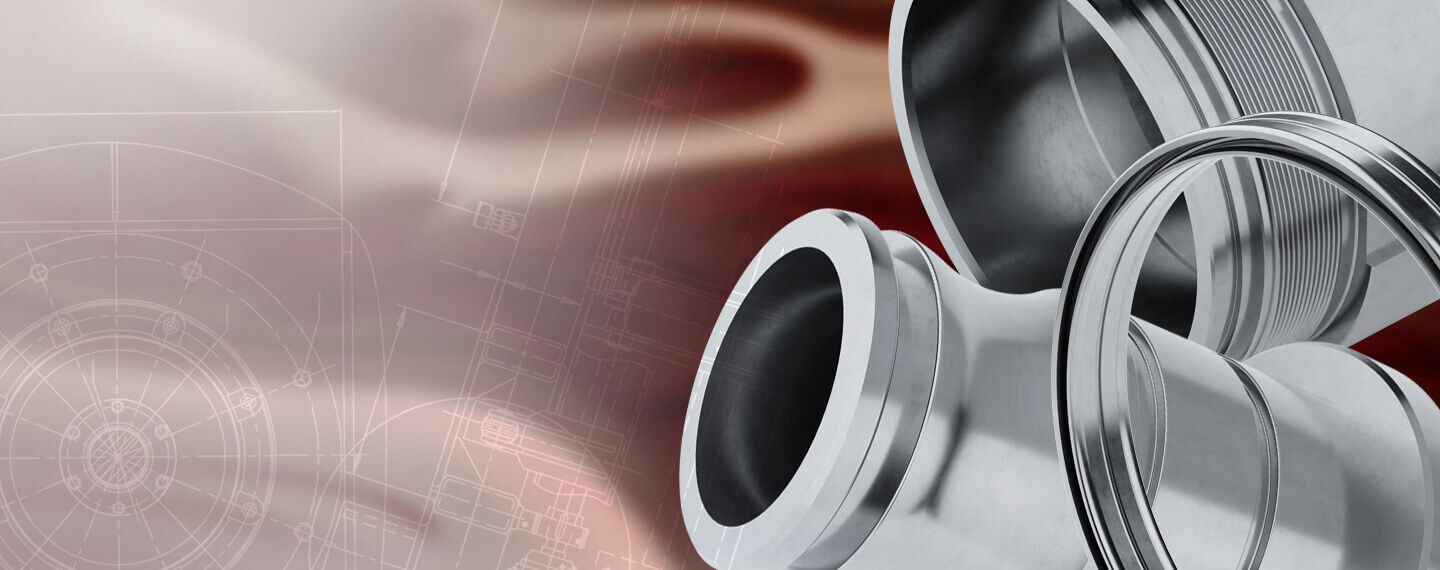

Graphite seat originally installed was facing ingress from the acidic media due to the ball valve movement. This was leading to pitting corrosion causing potential leaks and locking in place. The customer had restricted access to the valve reducing the window of opportunity to repair the valve.

Floating Ball Valve with a graphite seat

Graphite seat.

Working with the customer we developed a specifically designed metallic seat to a specification to suit the ball valve's hardness properties eliminating any risk of damage to the valve. We also machined a new ball and lapped together to ensure robust integrity. We took their existing design and modified the seats together with the ball in stainless steel material so it correctly located within their valve design for them during the next downtime to install.

The replacement was successful due to the mechanical properties of metal being able to survive the corrosive nature of the media in contrast to the graphite version of the seat which broke down. They customer is considering modifying their graphite seat valves to metallic designs for the future.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.