You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

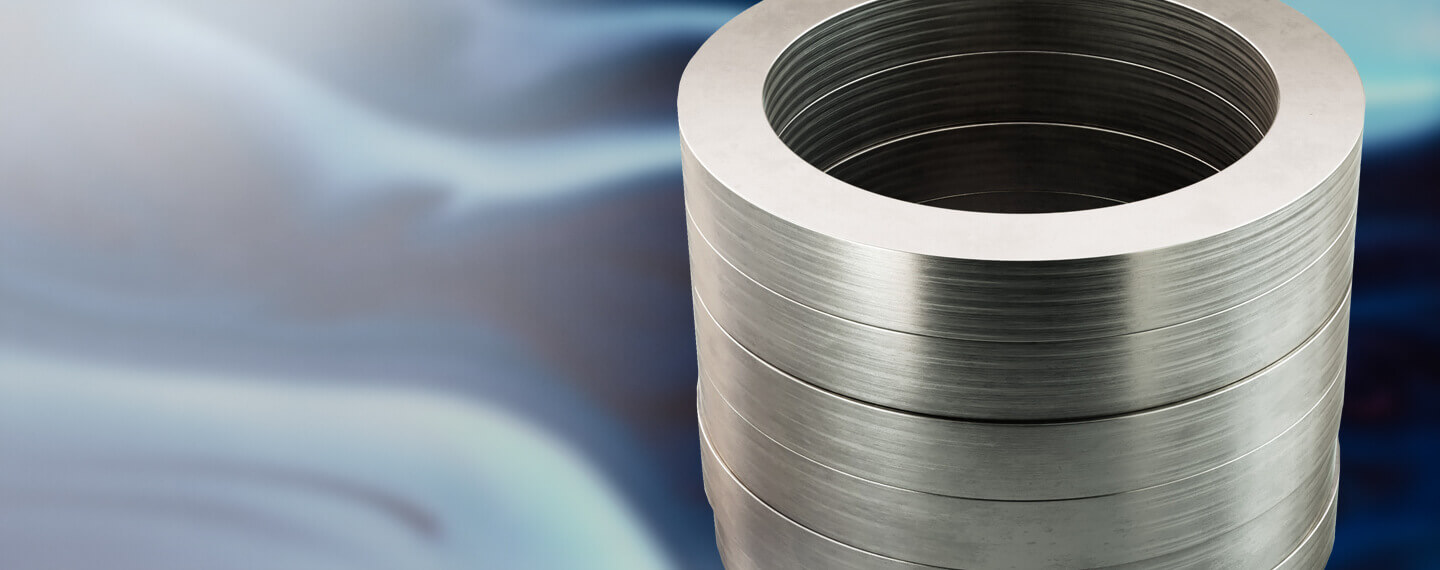

Graphite moulded rings with outstanding qualities.

Lionpak graphite moulded rings are high-efficiency, moulded graphite sealing rings, produced to precise density and size.

They are manufactured from expanded high purity flexible graphite foil with an oxidation inhibitor. They do not contain binders, elastomers or fillers.

The difference between the three model numbers is the purity of the graphite foil from which the rings are manufactured.

Valves and rotary equipment handling virtually any media. These rings are ideal for duties with high-temperature steam, demineralised water, heat transfer media, petroleum products, inorganic and organic acids, alkalis, hot waxes and oils.

Valve stem duties

Certain rotary equipment

Recommended ring densities

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.