You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

Specialised packing designed for use in hatch and tank lid seals on marine and inland waterway vessels

James Walker’s Tankatite 770 range of static packing has been specifically developed to meet the challenge of sealing tank lids, main hatches, inspection and cleaning covers on tankers and inland waterway barges.

The unique hybrid construction of the Tankatite 770 and Tankatite 770 MC products ensures that a uniform clamp load can be maintained in the product as bolting compressive load is applied. This allows the packing to compensate for housing surface imperfections as well as storing energy for repeated open and closing lid cycle requirements.

The materials and construction of this product make it suitable for vessels carrying all known bulk liquid cargoes in a range of International Maritime Organisation (IMO) classes.

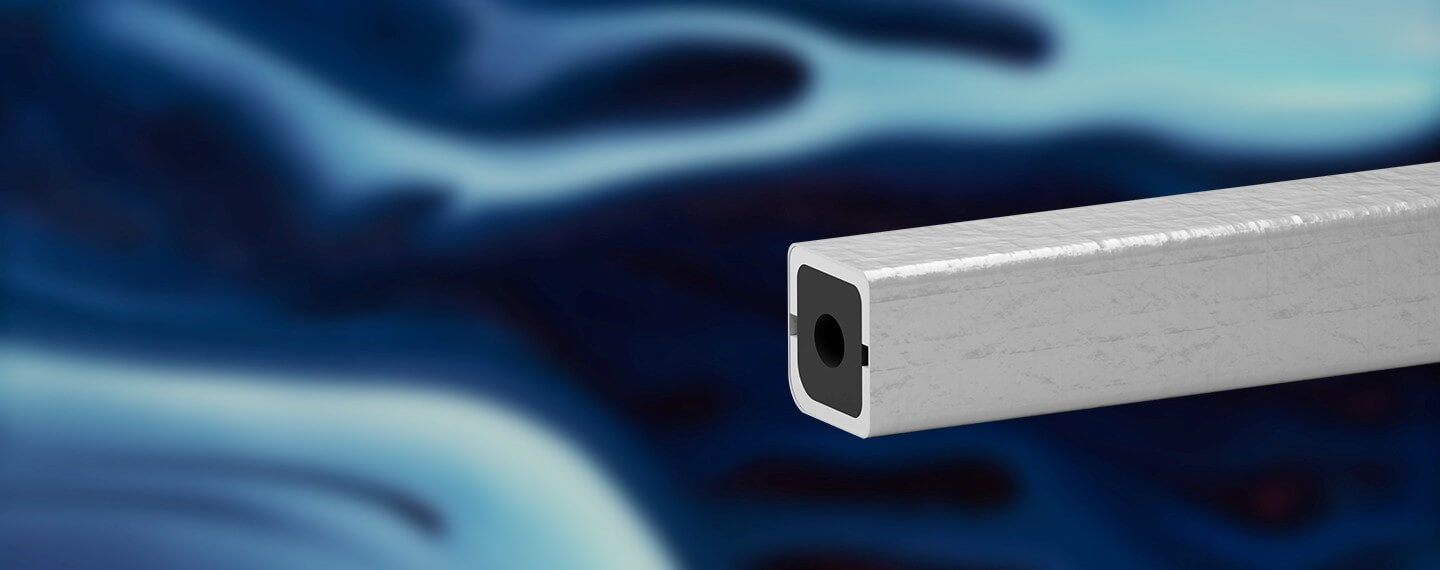

Tankatite 770 - elastomeric core encased in a jacket of expanded PTFE, with an outer layer of spirally wrapped PTFE tape to finish. This jacket and wrapped PTFE layer configuration creates an impermeable barrier to liquids and gases, ensuring effective zero emissions static lid sealing.

Tankatite 770MC variant features an elastomeric core wrapped with a PTFE tape; this is then encased in a jacket of expanded PTFE which secures additional expanded PTFE shims that are added to achieve the desired packing size; the whole construction is then once again spirally wrapped in an outer layer of PTFE tape to finish. The jacket and wrapped PTFE layer configuration creates an impermeable barrier to liquids and gases, ensuring effective zero emissions static lid sealing.

Any square or rectangular sections of 12.5mm (1/2”) upwards, made to order to suit customer housing sizes in round, square, oval or non-standard cross sections. Packing supplied in endless or split configurations to fit specific lid recess diameters/ sizes.

Packing section of 12.5 mm (1/2”) upwards.

Available in endless or split configurations for hatch sizes from Ø100 mm up to Ø3500 mm

Maximum Temperature:

+120°C (+248°F)

Minimum Temperature:

-50°C (-58°F)

Traditional gaskets and packing seals often provide an effective initial sealing force when first installed but all too often their essential elasticity and rebound is lost after being compressed under load. This allows leak paths to occur following repeated opening and closing cycles and fugitive emissions to escape to the atmosphere. This problem is made worse on older hatch and tank lid housings where irregularities from corrosion or impact damage also compromise sealing effectiveness.

The solution to these issues lies in the unique hybrid construction of Tankatite 770. Developed in cooperation with a major designer and manufacturer of hatch equipment, the product comprises a hollow elastomeric core, which provides conformability to adapt to different housing configurations contained in a shell and wrap of chemically resistant PTFE to form an outer impermeable sealing layer.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.