You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

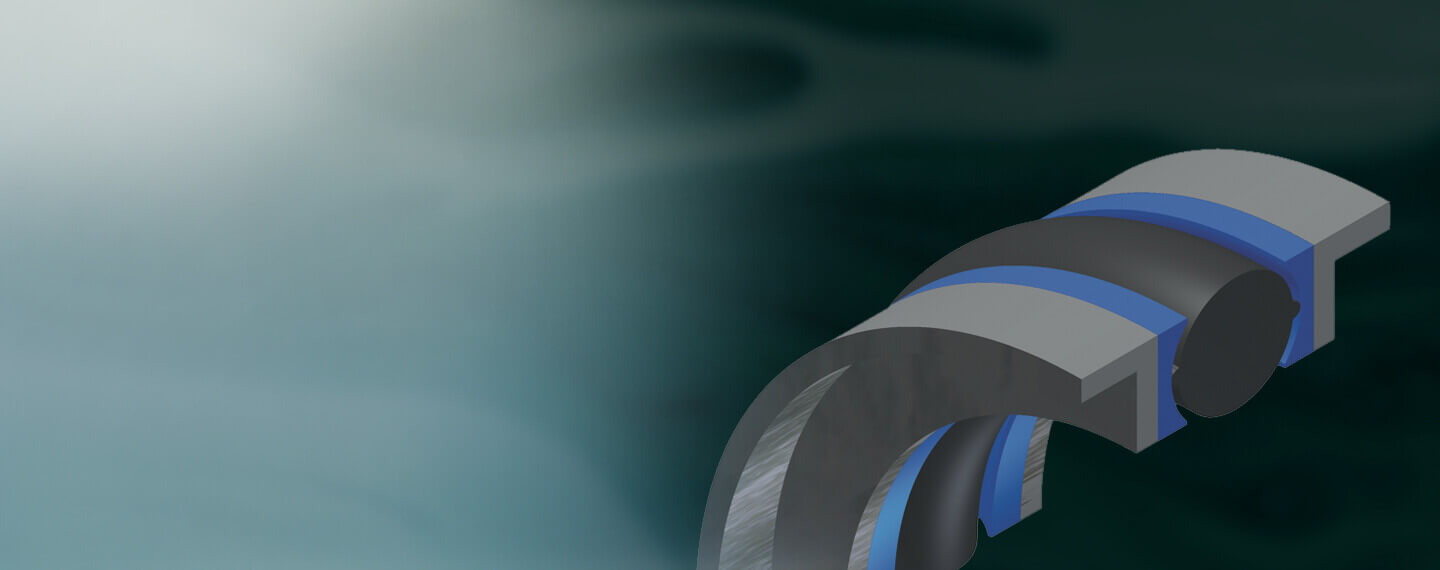

A five‑piece, double‑acting seal with split anti‑extrusion and wear rings.

Lionsele SP is designed for use on spool type or single-piece pistons, and is also suitable for use on two-piece piston assemblies.

This seal comprises an elastomeric sealing element, two anti-extrusion rings and two rigid thermoplastic wear / guide rings.

The elastomeric sealing element has an interference fit with the housing to ensure sealing integrity even at low pressures. The anti-extrusion rings prevent extrusion of the sealing element at higher pressures, whereas the wear/guide rings act as bearings to align the piston within the cylinder bore.

Suitable for use with most mineral-based hydraulic fluids, and most fire-resistant fluids of the water/oil emulsion and water/glycol types, at temperatures up to +100°C (+212°F). Also resistant to air, water and most lubricating oils and greases.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.