You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

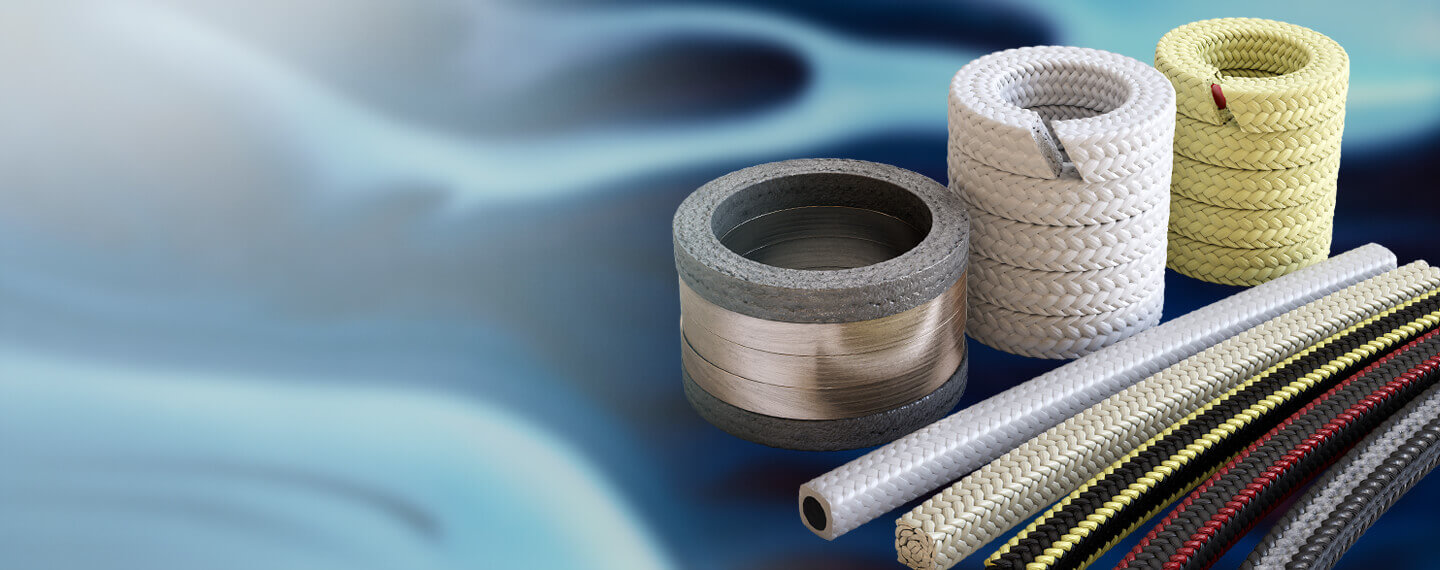

Complete performance for all applications. Our compression packings and braided packings are highly versatile, simple to install and cost effective when it comes to plant downtime and materials.

Our constant advances in materials and lubricants, product design and manufacturing techniques keep us at the forefront of compression packing technology. We therefore bring you one of the broadest compression packing ranges, which can be matched with the temperatures, pressures and speeds of your most modern fluid handling systems, and economical packings for your older plant.

Many of our compression packings will dramatically reduce your stockholding levels - as one carefully selected length-form product can often be used for many different valves, pumps and other fluid handling plant at your site.

Download our compression packing/braided packing guide for more information.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.