You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

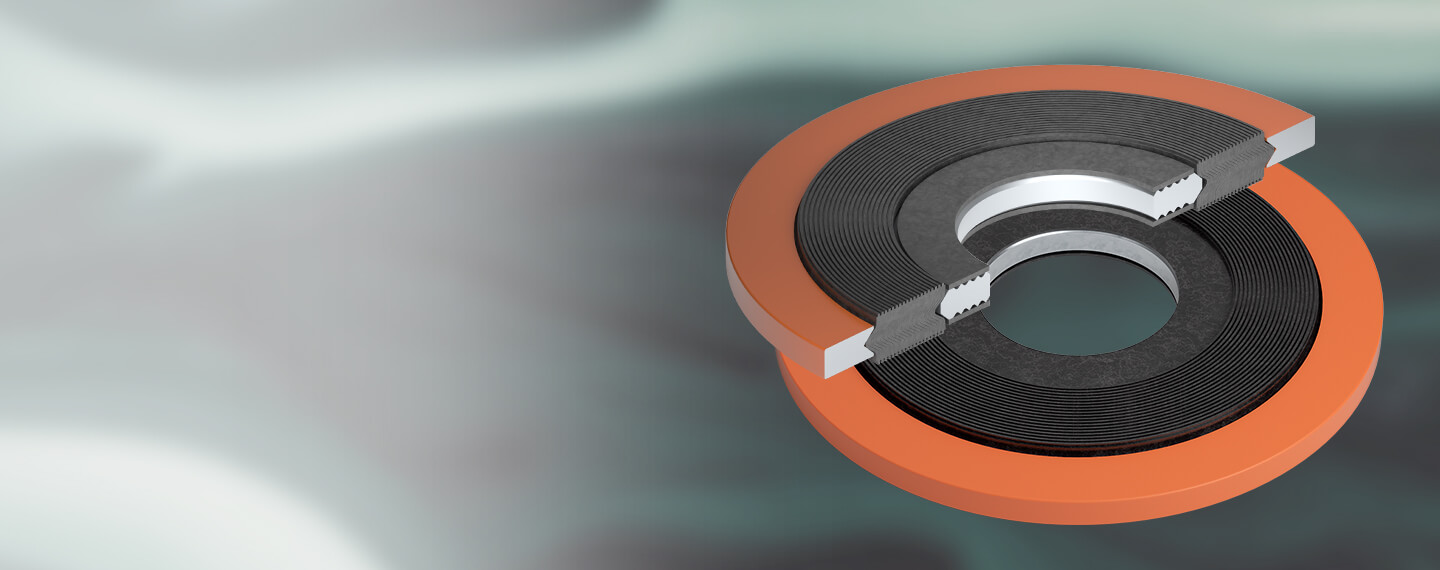

High integrity piping gasket delivering flange face protection from corrosion attack in HF alkylation service

Offering leak tightness behaviour far exceeding the performance of ‘standard’ spiral wound gaskets traditionally used in the HF alkylation process, Metaflex SG/IR-CK provides the additional benefit of preventing flange face damage caused by chemical cell corrosion.

Both winding and filler materials can be matched to specific applications.

Maximum Temperature: +500°C (+932°F)

Minimum Temperature: -196°C (-321°F)

Traditional spiral-wound gaskets do not provide a secure barrier against aggressive or corrosive media stagnating between the inner ring and the flange surfaces. Over time this can result in the formation of a chemical corrosion cell and lead to flange face corrosion, pitting and loss of material.

Damaged flange faces only become evident when the flanges are broken down during a planned shutdown and there is often no time to address or rectify the damage and therefore a standard spiral-wound piping gasket is once again installed and the problem continues to get worse.

Assessing the level of pitting or corrosion can be open to interpretation and there are no guarantees that simply replacing with a like-for-like gasket will provide the 'tightness' or 'leak-free' connection required when the plant is brought back into service

The Metaflex SG/IR-CK has been designed using a LoLode construction which allows the spiral-wound sealing element to easily compress down to the centring compression stop.

The inner ring has serrated grooved surfaces (Kammprofile) and soft graphite layers which are easily consolidated during assembly and then form a barrier to the ingress of media. This inner ring corrosion protection seal prevents media penetration and the resulting formation of corrosion cells at the flange faces.

The faces remain in good condition for the duration of the service and remain suitable for refitting with a replacement SG/IR-CK gasket at the next routine shutdown or scheduled maintenance event.