You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

The transition piece bolts on an onshore wind turbine were losing excessive amounts of tension due to vibration and relaxation. The necessary scheduled maintenance checks were still carried out by hydraulic tooling and were too costly for the turbine operator to continue without improvement.

The application was a new self-erecting tower technology designed for hub heights greater than 120 m.

Standard maintenance schedule and hydraulic tension tightening, with no appreciation of load transfer relaxation.

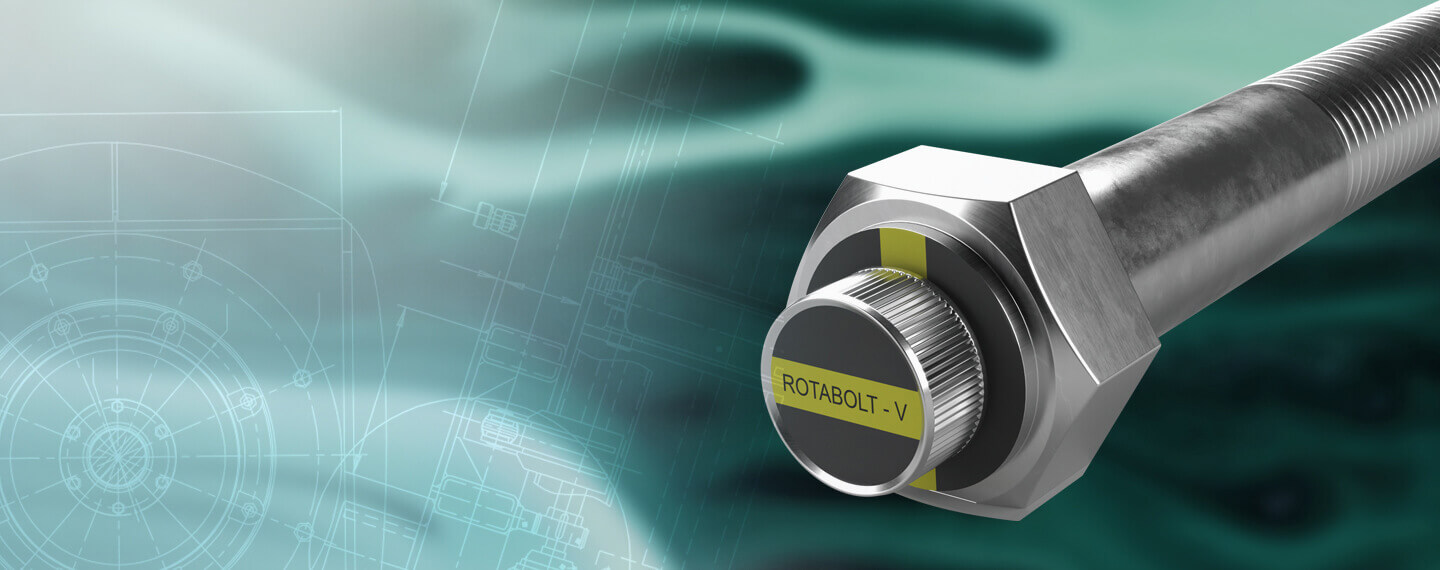

RotaBolt Vision was supplied, giving ongoing load monitoring and the ability to use drone inspection. Bolt loads can now be inspected quickly and safely. By only tightening those where tension has dropped below the minimum calibrated design limit, Rotabolt removes the need for costly time-consuming hydraulic tensioning on every bolt.

Safer maintenance using drone inspection.

The customer now monitors bolts with a drone while the maintenance technician is safely on the ground, very often no re-tightening is required and therefore no working at height risk, heavy tool use or time is wasted. A correct load is also now confirmed instead of estimated following relaxation after installation.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.