You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

The customer was experiencing failures of casing cover bolts in service on average every 5-6 weeks. This created a lot of unnecessary downtime and led to rising maintenance and material costs. The root of the problem could be traced back to installation procedures, whereby the bolts on the casing cover were simply torque tightened.

Large paper mill facilty in the US.

¾" (M20) - 10UNC stainless steel bolts.

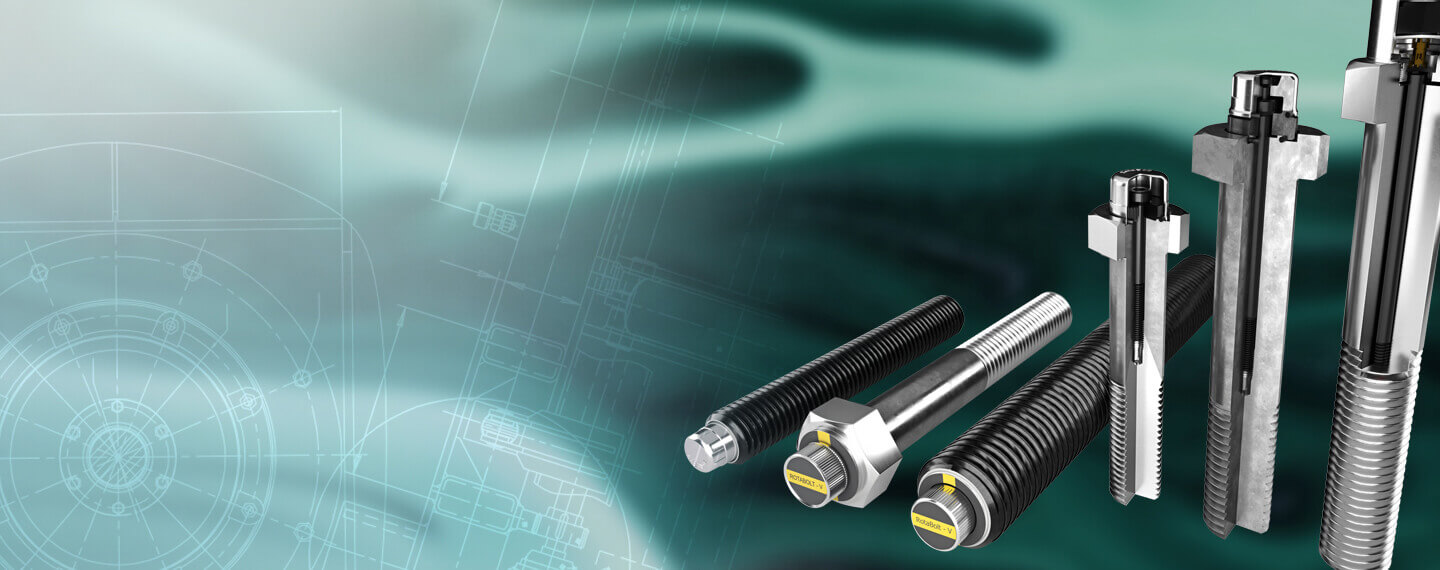

Existing bolts were replaced with RotaBolt RB1 Touch, which accurately measures tension so that it can be correctly achieved, maintained and monitored and ensures that installation is not reliant on torque tightening. A quick and easy tactile check of the bolt load ensures that regular maintenance checks can be made during operation without incurring downtime of the process.

Since the introduction of RotaBolt technology, the customer has eliminated the problem of bolts snapping during tightening. This is due to controlling tension during installation and using the RotaCap indicator to determine that the correct tension has been achieved, which ensures that the bolts do not suffer fatigue-fail as a result of vibration and transverse forces.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.