You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

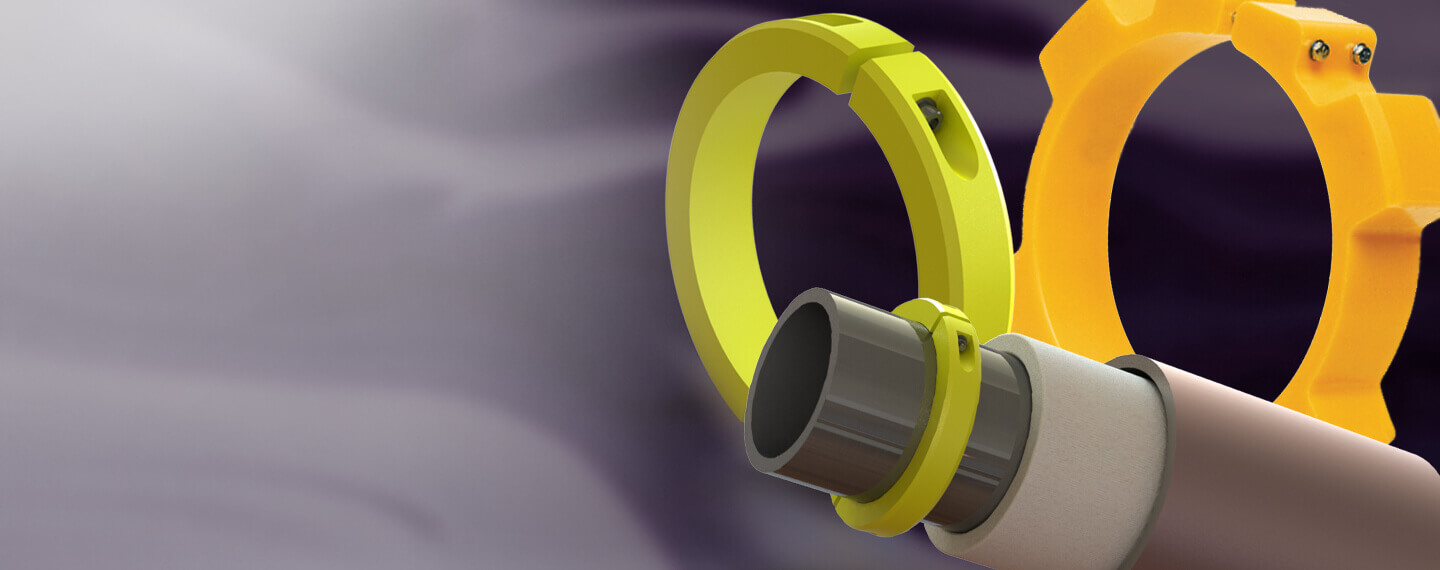

Commonly specified and requested components for subsea applications.

Our experts work closely with many of the world’s major oil companies and original equipment manufacturers to develop sealing solutions that deliver optimum performance in a range of hostile operating environments.

Through our innovative approach we identify areas where our materials will offer performance improvements and cost savings. The relevant grade of material is then selected, based on the requirements of the application, before using CAD technology to model and design components. We work in partnership with clients throughout the development process until the design is signed off and transferred to the manufacturing floor, where our bespoke facilities allow us to cast and machine individually tailored products capable of performing in the most demanding subsea environments.

These are some of the commonly specified and requested components for subsea applications, however we do manufacture a wide range of bespoke products. Please contact us for further details and to see how we can help with your subsea challenge requirements.

Riser clamps

Umbilical clamps

Piggy back clamps

Pipe handling clamps

Flowline bundle spacers

Pipe-in-pipe centralisers

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.