You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

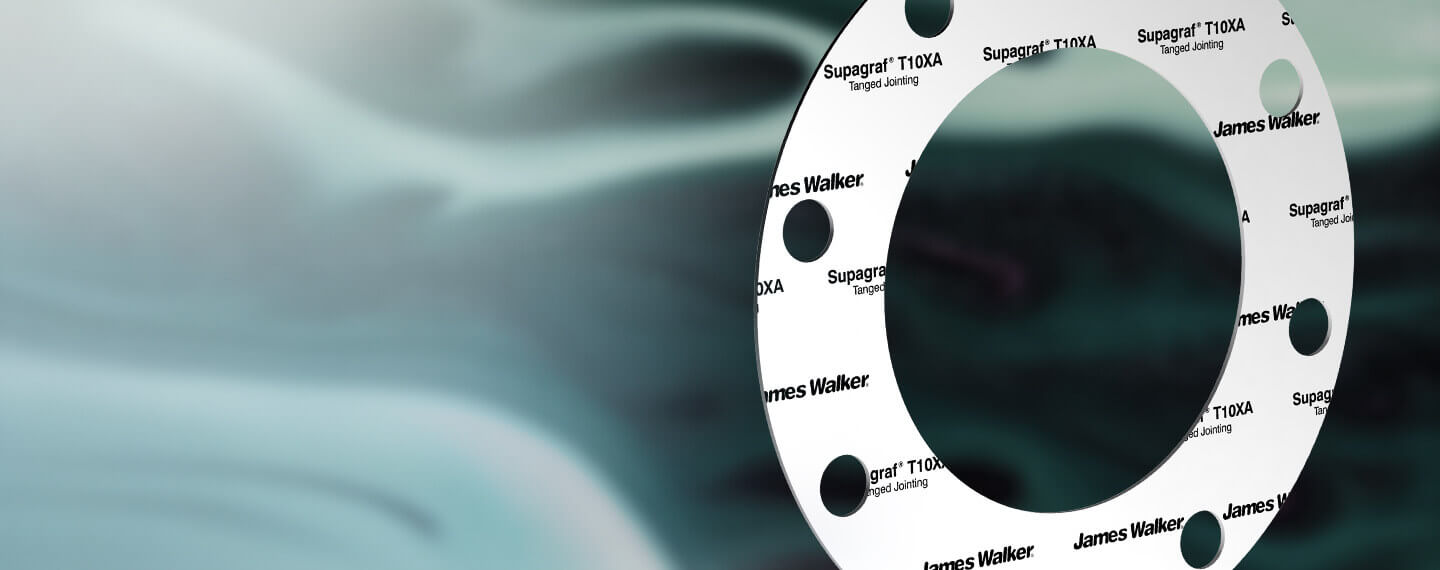

Supagraf T10XA is a high temperature / high pressure tanged core high grade sealing system with an anti‑stick surface treatment.

Supagraf T10XA is a highly oxidation resistant, tanged stainless steel reinforced flexible graphite gasket combining high quality flexible graphite with stainless steel reinforcement.

Supagraf T10XA is made of high oxidation resistant graphite foils which are mechanically attached to the stainless steel without using adhesives.

The operational life span of graphite at high temperatures might be limited due to media or environmental influences. Please contact us for continuous exposure in oxidising environments above +450°C.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.