You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

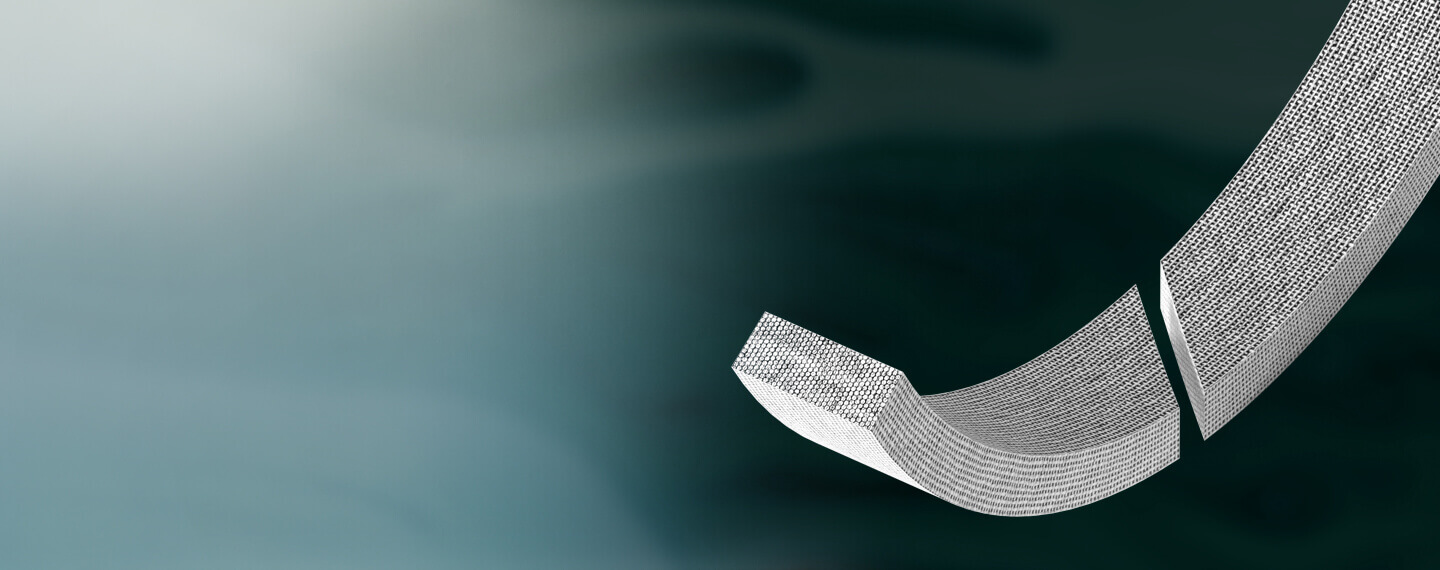

Our versatile and easy to assemble bearing strip with high resistance to wear and low coefficient of friction.

Lionsele B2 bearing strip has a low coefficient of friction. This tape-type bearing material is used within a hydraulic system when relative movement needs to be accommodated between two metallic surfaces.

The plain rectangular bearing strip of synthetic fabric impregnated with thermosetting resin provides a cost-effective and easy-to-use alternative to traditional materials such as phosphor-bronze or lead.

Often used in conjunction with compact-type piston head seals in hydraulic systems to eliminate metal-to-metal contact and other problems associated with offset pistons.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.